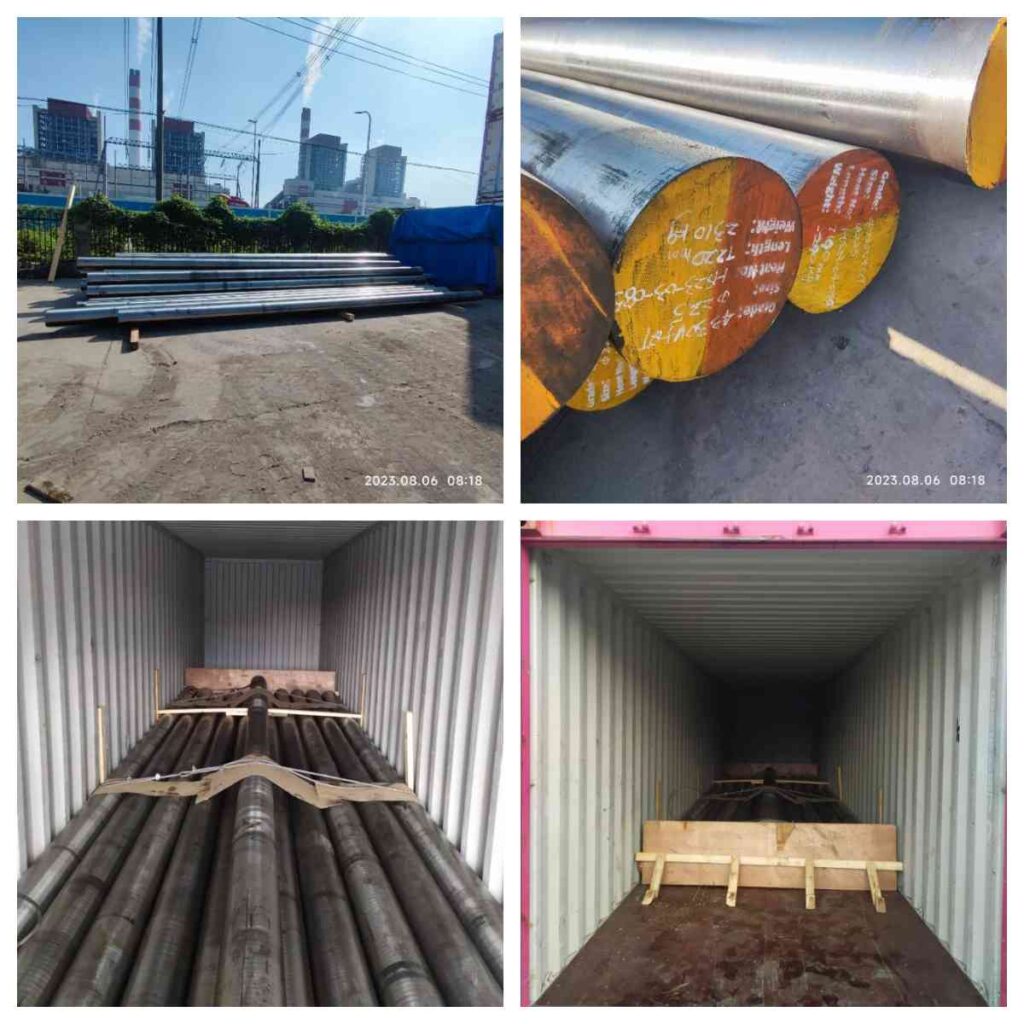

Reliably Delivering: 74 Tons of 4330V Forged Rounds to UAE Client Once Again

We extend our heartfelt appreciation to our valued client in the UAE for their continued trust in our products and services. It is with great pleasure that we announce the successful shipment of 74 tons of 4330V forged round bars to your esteemed organization once again. Your recurrent confidence in us stands as a testament to the quality, reliability, and performance of our materials. We remain committed to exceeding your expectations and look forward to many more successful collaborations in the future. Thank you for choosing us as your preferred supplier.

Order Share

| S.R. No. | Steel Grade | Dimensions (MM) | Quantity | ||||

| Diameter | Length | PCS | Packages | Net

Weight |

Gross

Weight |

||

| MM | MM | TONS | TONS | ||||

| 1 | AISI 4330V | 225 | 6250-7540 | 13 | 13 | 29.375 | 29.375 |

| 2 | AISI 4330V | 225 | 7140-7360 | 13 | 13 | 30.280 | 30.280 |

| 3 | AISI 4330V | 225 | 6830-7330 | 6 | 6 | 13.70 | 13.70 |

| TOTAL | 32 | 32 | 73.355 | 73.355 | |||

**Introduction**

In the realm of industrial materials, the 4330V forged round bar stands as a symbol of strength, durability, and versatility. Renowned for its exceptional mechanical properties and wide-ranging applications, this article explores the unique features, manufacturing process, and the myriad benefits of the 4330V forged round bar.

**The Power of 4330V: A Mechanical Marvel**

The 4330V forged round bar derives its name from its unique alloy composition. Comprising high levels of chromium, nickel, and molybdenum, this alloy steel exhibits an impressive array of mechanical properties.

**Key Attributes of the 4330V Forged Round Bar**

- **Superior Strength:** The 4330V’s composition imparts remarkable tensile and yield strength, making it ideal for applications demanding load-bearing capabilities.

- **Toughness and Impact Resistance:** Exceptional toughness and impact resistance make this material suitable for situations where sudden shocks or heavy loads are involved.

- **Hardness Retention:** The alloy’s heat-treatable nature allows for precise control over hardness levels, ensuring the bar retains its strength even in extreme conditions.

- **Corrosion Resistance:** The presence of chromium enhances corrosion resistance, vital for applications in harsh environments, including offshore drilling and marine structures.

**Manufacturing Excellence: Forging the 4330V Round Bar**

The journey of a 4330V forged round bar begins with the selection of high-quality steel, followed by a meticulous forging process:

- **Melting:** The chosen steel is melted in a controlled environment to ensure the desired chemical composition.

- **Forging:** The molten metal is then carefully shaped into round bars using mechanical force, often employing hydraulic presses or hammers. This process aligns the grain structure, enhancing strength.

- **Heat Treatment:** The forged round bars undergo a precise heat treatment regimen, which may include quenching and tempering. This imparts the desired mechanical properties, including hardness and toughness.

- **Machining and Finishing:** The bars are meticulously machined to meet precise dimensional specifications and surface finish requirements.

**Applications Across Industries**

The versatility of the 4330V forged round bar shines through in its broad range of applications:

- **Oil and Gas:** In drilling tools, downhole components, and high-pressure systems, the 4330V excels due to its strength, corrosion resistance, and fatigue resistance.

- **Aerospace:** This material finds use in aircraft landing gear, structural components, and engine parts where a combination of strength and weight reduction is crucial.

- **Heavy Machinery:** In gears, shafts, and axles, the 4330V’s durability and toughness ensure machinery can withstand demanding loads.

- **Marine:** For marine shafts, propellers, and other critical components exposed to harsh saltwater conditions, the corrosion resistance of 4330V is invaluable.

**Elevating Engineering Possibilities**

The 4330V forged round bar represents a pinnacle of metallurgical achievement. Its extraordinary blend of strength, toughness, and corrosion resistance has elevated it to a key player in a wide array of industries. As technology advances, this material continues to enable new possibilities in engineering, promising to be a reliable choice for those who demand the utmost in material performance and durability.