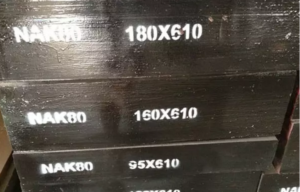

NAK80 plastic mould steel, a Ni Al Cu precipitation age-hardening steel, is characterized by high polishability. NAK80 plastic mould steel is sulphurized to give the steel good machinability, mirror finish and electrical discharge machinability, with good The weldability of the welded part of the hardness first decreases, and after the aging treatment and air cooling at 500°C × 5 hours after welding, its hardness decreases. The hardness and the heat affected zone are the same as the hardness of the base material.

NAK80 die steel is gas-nitrided to a surface hardness of 750 HV, which increases service life. fushun Metal’s NAK80 plastic mold steel is specially melted and produced for high purity, stability and processability. Excellent performance, easy to fill welding, uniform hardness, good polishability, excellent finish, easy to grind and process after discharge processing, easy to use. Excellent characteristics such as surface galling and long service life.

Fushun Metal’s NAK80 pre-hardened plastic mold steel can be polished without any heat treatment. Good and good etching properties. May be related to the sulfur content, in general NAK80 die steel shall not be made directly EDM skin.

NAK80 plastic mould steel is widely used in plastic moulds for transparent products, optical and electronic products, good surface finish is required. Electro-etching molds for smoothness, long term production of high hardness precision molds, mirror polishing molds, TV filters, cosmetic cases, moving molds, etc. On top of die steel such as inserts.

NAK80 is an improved version of NAK55 die steel (mirror polishing, discharge machining, ductility), and in addition to having the following features In addition to all the features of the NAK55, the NAK80 has excellent mirror polishability and an attractive surface for electrical discharge machining, which can replace pear skin etching. The NAK80 is designed for applications where transparency and mirror polish are important.