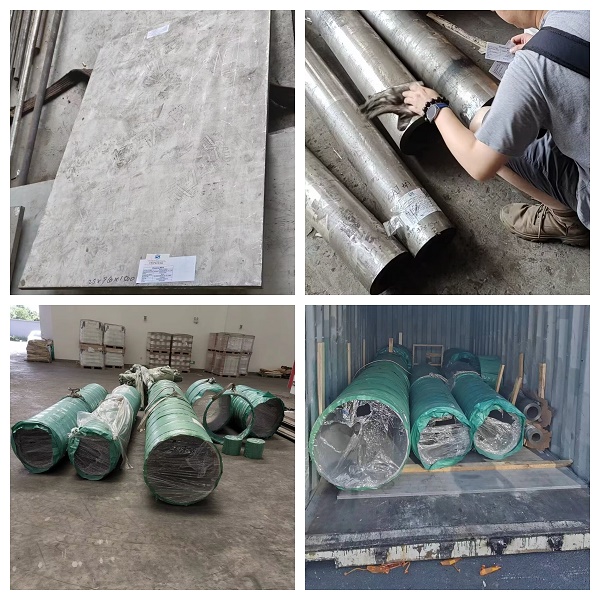

Joy and Gratitude as We Deliver to Our Valued Customer in Turkey

As we proudly ship our products to our esteemed customer in Turkey, our hearts are filled with immense joy and gratitude. This moment marks not just a transaction, but a meaningful collaboration that underscores the trust and partnership we’ve cultivated over time.

Order Share

| S.R. No. | Commodities Name | Steel Grade | Diameter /Width |

Thickness | Length |

| (mm) | (mm) | (mm) | |||

| 1 | Nickel alloy pipe | A554 MT-330 |

762 | 25 | 4134 |

| 2 | 842 | 25 | 376 | ||

| 3 | 842 | 25 | 983 | ||

| 4 | 762 | 25 | 1300 | ||

| 5 | 580 | 25 | 3415 | ||

| 6 | 580 | 25 | 3426 | ||

| 7 | 220 | 37 | 985 | ||

| 8 | 155 | 30 | 1680 | ||

| 9 | 273.1 | 15 | 245 | ||

| 10 | Nickel alloy sheet | SS 330 / SUH330 (1.4864) | 1250 | 12 | 1500 |

| 11 | 1150 | 15 | 1800 | ||

| 12 | 1500 | 20 | 3000 | ||

| 13 | 1000 | 25 | 2100 | ||

| 14 | 1000 | 25 | 1930 | ||

| 15 | 1500 | 25 | 960 | ||

| 16 | 650 | 50 | 1000 | ||

| 17 | Nickel alloy bar | SS 330 / SUH330 (1.4864) | 25 | / | 960 |

Introduction

In the world of advanced materials, the 1.4864 nickel-based alloy steel stands out as a remarkable engineering innovation. Renowned for its exceptional combination of mechanical properties, resistance to corrosion, and high-temperature stability, this alloy has found its way into a myriad of industrial applications. In this article, we delve into the composition, properties, and applications of 1.4864 nickel-based alloy steel.

Composition

The superior attributes of 1.4864 nickel-based alloy steel can be attributed to its precisely balanced composition. The table below presents its elemental breakdown:

Nickel (Ni) | Chromium (Cr) | Iron (Fe) | Manganese (Mn) | Silicon (Si) | Carbon (C)

70-75% | 18-21% | 5-8% | 1.5-2.5% | 0.5-1.0% | 0.08% max

Mechanical Properties

1.4864 nickel-based alloy steel’s mechanical prowess makes it indispensable in demanding environments. Below are its key mechanical properties:

- High Tensile Strength

With a tensile strength ranging from 800 to 1100 MPa, this alloy exhibits exceptional resistance to deformation under stress, making it suitable for load-bearing applications.

- Impressive Hardness

The alloy boasts a hardness range of 220 to 260 HBW, signifying its ability to resist wear and abrasion even in harsh conditions.

- Superior Creep Resistance

At elevated temperatures, 1.4864 alloy maintains its structural integrity due to its impressive creep strength, ensuring reliability in high-temperature applications.

Corrosion Resistance

One of the most striking features of 1.4864 nickel-based alloy steel is its resistance to corrosion, which is essential for applications in corrosive environments. The alloy’s chromium content forms a protective oxide layer on the surface, rendering it highly resistant to oxidation and corrosion by various acids, alkalis, and gases, even at elevated temperatures.

High-Temperature Stability

The ability to retain its mechanical properties at elevated temperatures is a hallmark of 1.4864 alloy steel. This property makes it suitable for applications in industries like aerospace, power generation, and chemical processing, where exposure to high temperatures is unavoidable.

Applications

- Aerospace Industry

The alloy’s combination of high-temperature stability and mechanical strength makes it ideal for components in jet engines, where it can endure extreme temperatures and mechanical stresses.

- Power Generation

In power plants, where high temperatures and aggressive environments are commonplace, 1.4864 alloy is used for boiler components, superheaters, and reheaters due to its excellent corrosion and oxidation resistance.

- Chemical Processing

The alloy finds its place in the chemical industry, where it is used for manufacturing reactors, heat exchangers, and other equipment that come into contact with corrosive chemicals at elevated temperatures.

- Petrochemical Industry

With its resistance to sulfur-containing atmospheres and high-temperature stability, 1.4864 alloy is employed in petrochemical applications, including catalytic crackers and reforming units.

In the realm of advanced materials, the 1.4864 nickel-based alloy steel shines as a testament to human ingenuity and engineering excellence. Its precisely crafted composition, coupled with outstanding mechanical properties, corrosion resistance, and high-temperature stability, makes it an indispensable player in critical industries. From aerospace to petrochemicals, this alloy continues to enable technological advancements that push the boundaries of what’s achievable.