Hot Work Tool Steel Bright Small Rod

Introduce

We, Fushun Company, possess extensive experience in tool steel production over the years. We have optimized the production process for hot work tool steel small bars, achieving effective cost and quality control. We are capable of supplying customers with hot work tool steel round bars in diameters ranging from 3.3 to 16 millimeters, featuring a polished surface. Our offerings come with competitive pricing and consistent quality. These bars are well-suited for applications such as making punches and dies.

Advantage

- Diameter ranging from 3.3 to 16 millimeters

- Delivery in annealed condition

- Polished surface finish

- Minimal production wastage

- Guaranteed composition

- Stable quality

- Competitive pricing

Grade

| Mat. No. | EN | AISI/ASTM/SAE |

| 1.2343 | X37CrMoV5-1 | H11 |

| 1.2344 | X40CrMoV5-1 | H13 |

| 1.2345 | X50CrVMo51 | Approx. H11 |

| 1.2357 | ||

| 1.2365 | 32CrMoV12-28 | H10 |

| 1.2367 | X38CrMoV5-3 | – |

| 1.2581 | X30WCrV9-3 | H21 |

| 1.2714 | 56NiCrMoV7 | – |

| 1.2885 | X32CrMoCoV3-3-3 | H10A |

Chemical

| AISI/ASTM/SAE | C | Si | Mn | Cr | Mo | Ni | V | Others |

| H11 | 0.33-0.41 | 0.8-1.2 | 0.25-0.5 | 4.8-5.5 | 1.1-1.5 | – | 0.3-0.5 | – |

| H13 | 0.35-0.42 | 0.8-1.2 | 0.25-0.5 | 4.8-5.5 | 1.2-1.5 | – | 0.8-1.15 | – |

| 1.2345 | 0.48-0.53 | 0.8-1.1 | 0.2-0.4 | 4.8-5.2 | 1.25-1.5 | – | 0.85-1.1 | – |

| 1.2357 | 0.45-0.55 | 0.20-0.5 | 0.5-0.8 | 3.0-.3.6 | 1.2-1.6 | 0.05-0.25 | ||

| H10 | 0.28-0.35 | 0.1-0.4 | 0.15-0.45 | 2.7-3.2 | 2.5-3.0 | – | 0.4-0.7 | – |

| 1.2367 | 0.35-0.4 | 0.3-0.5 | 0.3-0.5 | 4.8-5.2 | 2.7-3.2 | – | 0.4-0.6 | – |

| H21 | 0.25-035 | 0.1-0.4 | 0.15-0.45 | 2.5-3.2 | – | – | 0.3-0.5 | 8.5-9.5 |

| 1.2714 | 0.50-0.6 | 0.1-0.4 | 0.6-0.9 | 0.8-1.2 | 0.35-0.55 | 1.5-1.8 | 0.05-0.15 | |

| H10A | 0.28-0.35 | 0.10-0.40 | 0.15-0.45 | 2.70-3.20 | 2.60-3.00 | – | 0.40-0.70 | Co 9.50-10.5 |

* If you not find, welcome send your inquiry with steel grade to us!

Who we are

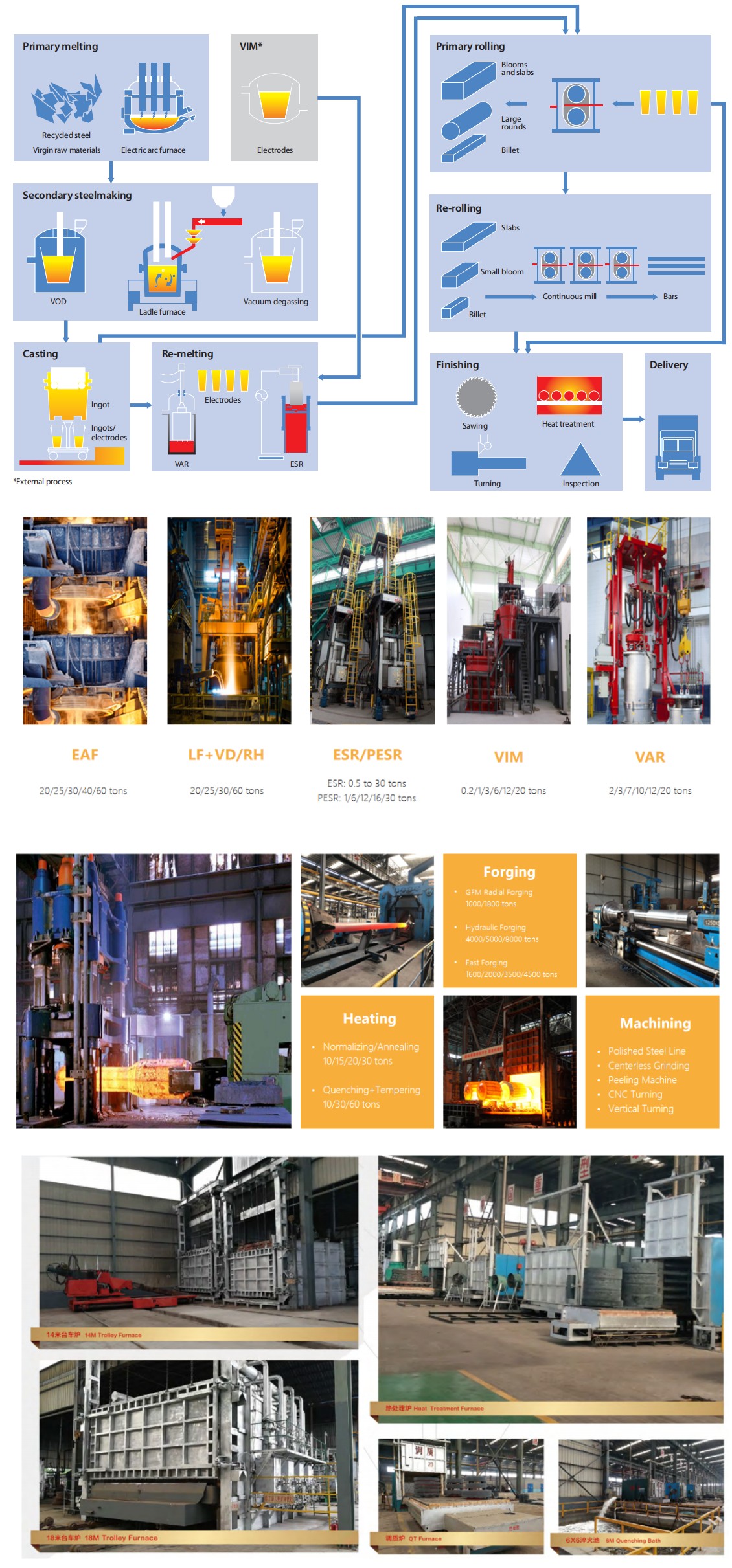

We, Fushun Special Steel, are one of the leading manufacturers of special steel in China. Our reputation as experts in the field of special steel products is based on 20 years of tradition in the production of specialty steel. This experience, together with modern production facilities and highly trained staff, is the foundation on which the high quality of our products is based. We are able to offer much more: starting with skilled technical advice, our customers benefit from a one-stop service including melting, forming and heat treatment through to processing and delivery of the desired material.

What we do

We have more than 400 employees and our plant covers an area of nearly 15,000 square meters, with an annual output of 100,000 tons. The manufacturing bases have the advantage of advanced technology and modern equipments like 30/50/60ton electric arc furnaces (EAF), 30/60ton refining furnaces (LF), 30/60ton vacuum furnaces (VD/VOD), 1-15ton electro slag remelting (ESR), 6/12/30ton PESR, 1/3/6ton VIM, 3/7ton VAR; 8000t hydraulic press machine, 1800t precision forging machine (GFM), a varied range of electro-hydraulic hammers and rolling mill machines such as 250, 350, 550 and 850 rolling mills; Various other large-scale machining & processing & inspection equipments.

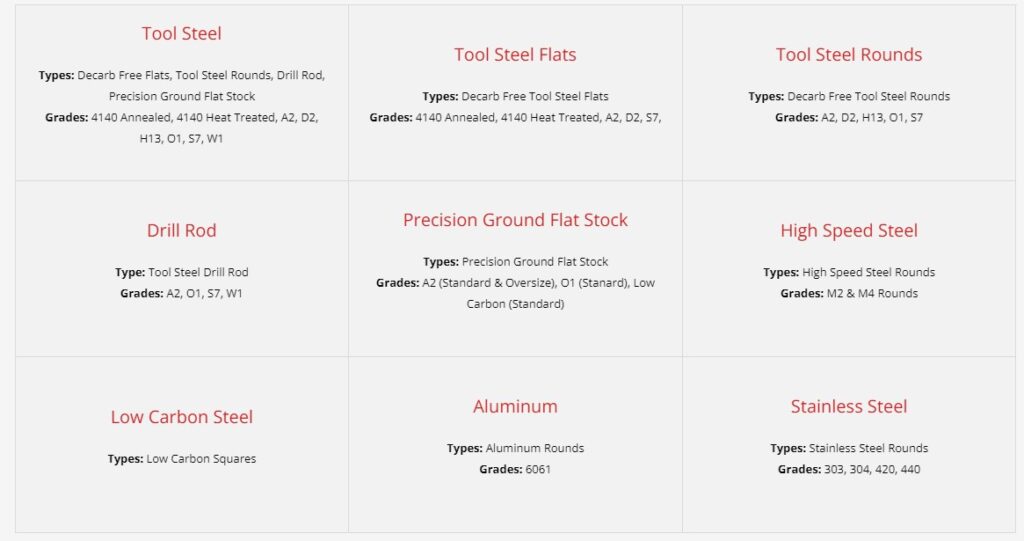

Fushun Special Steel is experienced in manufacturing more than 5400 grades of special steels including superalloy, ultra-high strength steel, stainless steel, tool and die steel, titanium alloy, alloy structural steel, high-speed steel, which are widely applied in the field of aviation, aerospace, weapons, nuclear power, petroleum and petrochemical, transportation, engineering machinery and medical.

We can understand what you need

With 36 years of knowledge in serving the marine and offshore industry, we are able to understand your technical requirements.

We can give you what you require

With 15,520 line items in our inventory, we are able to meet your hydraulic component requirements.

We can give you the parts now

We understand that you want the items fast. We are committed to delivering ex-stock items within 3 working days.

We can ship our products to where you are, globally

With our experience in serving the global community, we are well versed in preparing various documents that you require for export declarations.

We can give you quality services to ISO 9001 standards

Our work processes are certified in accordance to ISO 9001 quality management principles. Please click here to view our ISO 9001 certificate.

Take advantage of our:

› Flexibility: we can offer low mill production order quantities

› Quality control: throughout the entire production process

› Individuality: we can manufacture a wide range of dimensions with tight tolerances

› Close customer relationships: thanks to our lean and flat company structure and worldwide presence

› Competence: due to the Know How of our experienced staff

› Problem solving: together we will help develop entirely new products

OUR VISION

Our goal is to be the fastest, most reliable, quality provider of XXX in the world.

To enhance the lives of our team, our customers, our suppliers, and our community.

- Business Strategies

- Fast

- Quality

- High-Efficiency

- Save-Time-And-Costs

- Customer-Oriented

OUR CLIENTS

Our commitment to excellence and reliability has resulted in long-standing partnerships with some of the biggest names in the industry. Like General Electric (GE), Thyssen Krupp, Bosch,Honeywell etc. We also have established partnerships with several prominent Chinese steel groups, like BaoWusteel, CITIC etc.

What Our Customer Are Saying…

We often buy special steel raw materials from Fushun Special, their quality is stable, the delivery time is fast and the team is professional. Fushun Special are able to suggest professional solutions to our various problems. I feel very relieved and happy to work with Fushun.

Services

Our business is built on providing great service. It’s simple: we do what we promise and continue evolving to meet our customers’ changing needs. Ryerson’s customers know they get industry leading support and service for the metal components they need to run their businesses efficiently.

Our customers are an important part of this process, and we respond to their needs. We support them with initial design, appropriate material selection, actual production and test certification right through to the delivery of their tubes. Our aim is to provide companies around the world with a clear competitive advantage based on outstanding quality and forward thinking.

Providing More than Metal

We offer the products and services to help you deliver more with fewer resources.

Streamlining Your Supply Chain

In response to changing demands, we partner with you to deliver supply-chain solutions tailored to meet the needs of your business.

Supply Chain Services

With locations worldwide, Ryerson draws from a broad base of unique supply chain services to assemble the right combination that produces the ideal solution for your business. From start to finish, we’ll manage logistics across all phases of the supply chain.