Hot Stamping Mould Tool Steel

Fushun are main manufacturer of tool steel for Hot Stamping Mould.

What is Hot Stamping Mould?

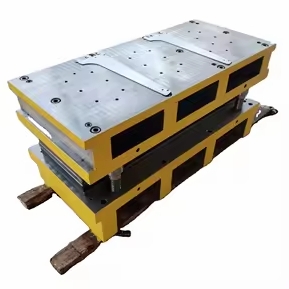

Hot stamping moulds (or Hot punching moulds) are specialized tooling systems designed for forming and punching metal components at elevated temperatures. These moulds incorporate sophisticated heating and cooling systems, precise punching elements, and thermal management features. The mould assembly must maintain dimensional accuracy while handling both high temperatures and significant punching forces, typically including integrated temperature control channels and specialized thermal insulation zones.

The primary function of hot stamping moulds is to produce high-strength components through combined heating, forming, and rapid cooling processes. They are extensively used in automotive and aerospace industries to manufacture structural components requiring high strength and precise geometry. This process is particularly effective for ultra-high-strength steel components, offering advantages such as reduced springback, improved formability at elevated temperatures, and enhanced final mechanical properties. The process can achieve complex geometries while ensuring consistent part quality and superior strength characteristics.

The mould materials used in hot stamping applications contain specific alloying elements to withstand both thermal and mechanical stresses. Premium grade tool steels are employed, incorporating combinations of chromium, tungsten, molybdenum, and vanadium to provide optimal performance at elevated temperatures. These materials offer excellent hot hardness, thermal fatigue resistance, and wear resistance under high-temperature conditions. The microstructure features thermally stable carbides that maintain hardness and dimensional stability during repeated thermal cycles. Advanced surface treatments and coatings are often applied to enhance wear resistance and thermal shock resistance, while sophisticated cooling systems help maintain precise temperature control during the stamping process.

Hot Stamping Mould Materials

| — | 8Cr3 | |

| H10 | 1.2365 | 4Cr3Mo3SiV |

| — | 3Cr3Mo3W2V |

Chemical Composition of Hot Stamping Mould

| Grade | C | Si | Mn | Cr | W | Mo | V |

| 8Cr3 | 0.75~0.85 | ≤0.40 | ≤0.40 | 3.20~3.80 | |||

| 4Cr3Mo3SiV | 0.35~0.45 | 0.80~1.20 | 0.25~0.70 | 3.00~3.75 | 2.00~3.00 | 0.25~0.75 | |

| 3Cr3Mo3W2V | 0.32~0.42 | 0.60~0.90 | ≤0.65 | 2.80~3.30 | 1.20~1.80 | 2.50~3.00 | 0.80~1.20 |

Properties of Hot Stamping Mould Steel

| Grade | Annealed HBW |

| 8Cr3 | 207~255 |

| 4Cr3Mo3SiV | ≤229 |

| 3Cr3Mo3W2V | ≤255 |

Available Shapes from Fushun

*Round Bar

*Flat Bar

*Block

*Plate

Contact Information

Welcome your inquiry. We will send you a free quotation within 24 hours.