Effect of Aging Process on Low-Temperature Mechanical Properties of 15-5PH Steel

15-5PH steel is a widely used precipitation-hardened stainless steel in the aerospace field. When cooled from the solution temperature to room temperature, its microstructure transforms into quenched martensite. After aging, due to the precipitation of copper-rich phases and carbides in the martensitic matrix, the strength is further improved. During production, a part made of 15-5PH steel experienced fracture at -50°C after undergoing solid solution treatment at 1040°C and aging at 485°C. Reviewing relevant literature on 15-5PH steel did not reveal specific descriptions of its low-temperature mechanical properties. To understand the low-temperature mechanical properties of 15-5PH steel under different aging processes, this study was conducted.

1 Materials and Methods

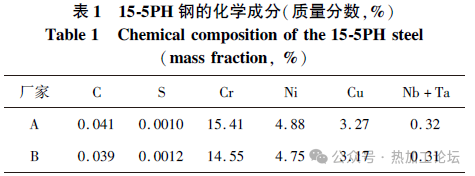

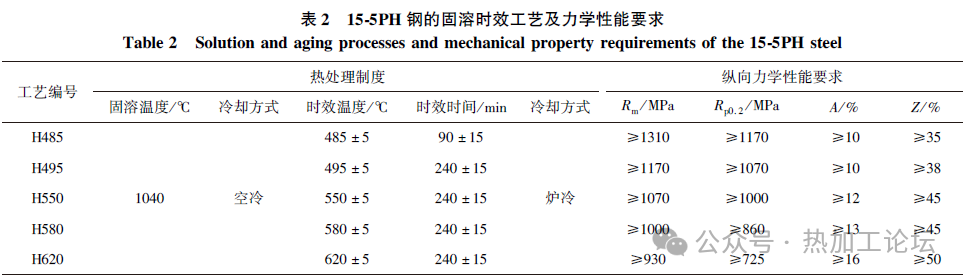

Steel samples from two different manufacturers, labeled A and B, were selected for testing. Their chemical compositions are listed in Table 1, with specifications of ϕ20mm × 300mm. Solid solution and aging treatments were performed according to the H485, H495, H550, H680, and H620 regimes specified in GJB 8268-2014 “Specification for Precipitation-Hardening Stainless Steel Bars for Aerospace Applications” using a vacuum hydrogen annealing furnace. Standard tensile specimens (R7) and Charpy V-notch impact specimens (55mm × 10mm × 10mm) were prepared according to GB/T228.1-2021 “Metallic Materials – Tensile Testing – Part 1: Method of Test at Room Temperature,” GB/T228.3-2019 “Metallic Materials – Tensile Testing – Part 3: Method of Test at Low Temperatures,” and GB/T229-2020 “Metallic Materials – Charpy Pendulum Impact Test.” Tensile and impact tests were conducted at room temperature and -50°C. The results of the room temperature and -50°C impact tests are averages of five parallel specimens, while the results of the room temperature and -50°C tensile tests are averages of two parallel specimens. Table 2 lists the specific heat treatment processes and corresponding mechanical property requirements.

2 Experimental Results and Analysis

2.1 Impact Performance

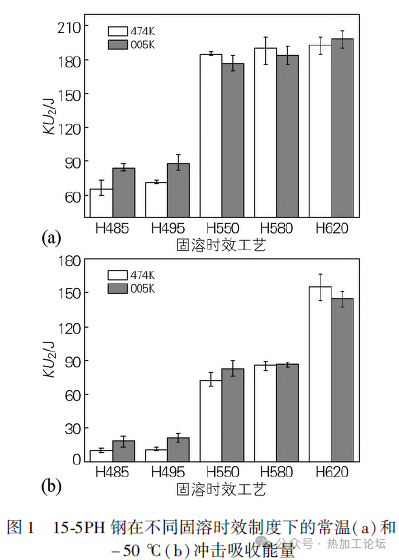

Figure 1 shows the room temperature and -50°C impact performance of batch 474K from manufacturer A and batch 005K from manufacturer B of 15-5PH steel. From Figure 1(a), it can be seen that the room temperature impact performance of 15-5PH steel from different batches of the same manufacturer is similar under the same aging regime. The room temperature absorbed energy is relatively low under the H485 and H495 regimes, and increases significantly with the increase in aging temperature, especially under the H550 regime, where the room temperature absorbed energy increases substantially compared to the H495 regime. The room temperature absorbed energy under the H580 and H620 regimes increases slightly but not significantly compared to the H550 regime. From Figure 1(b), it can be seen that the low-temperature impact performance of 15-5PH steel from different batches of the same manufacturer is also similar under the same aging regime. The low-temperature absorbed energy is relatively low under the H485 and H495 regimes, and increases significantly with the increase in aging temperature, especially under the H550 regime, where the room temperature absorbed energy increases substantially compared to the H495 regime. The low-temperature absorbed energy under the H620 regime increases substantially compared to the H580 regime. It can be concluded that both the room temperature and low-temperature impact performance of 15-5PH steel increase with the increase in aging temperature, but the trend is not linear.

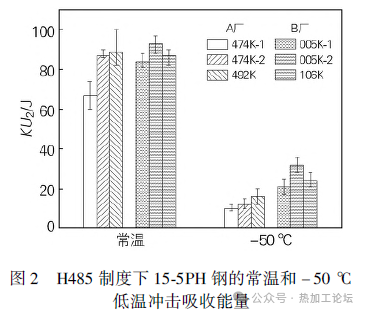

Figure 2 shows the room temperature and -50°C impact performance of 15-5PH steel from different manufacturers, different furnaces, and different batches under the H485 regime. From Figure 2, it can be seen that there is a significant difference in the room temperature and low-temperature absorbed energy of 15-5PH steel under the H485 regime. The lowest low-temperature absorbed energy is around 10J, and the lowest room temperature absorbed energy is around 60J. There is also a significant difference in the absorbed energy between different batches from the same manufacturer, and the absorbed energy varies to some extent uncontrollably.

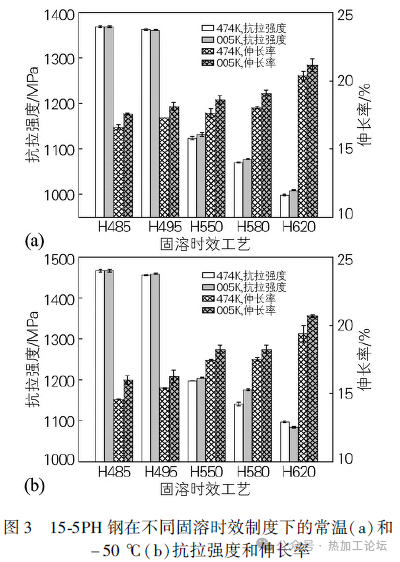

2.2 Tensile Performance

Figure 3 shows the room temperature and -50°C tensile performance of batch 474K from manufacturer A and batch 005K from manufacturer B of 15-5PH steel. From Figure 3(a), it can be seen that the room temperature tensile performance of 15-5PH steel from different batches of the same manufacturer is almost the same under the same aging regime. The room temperature tensile strength decreases significantly with the increase in aging temperature, while the elongation increases gradually. From Figure 3(b), it can be seen that the low-temperature tensile performance of 15-5PH steel from different batches of the same manufacturer is also almost the same under the same aging regime. The low-temperature tensile strength decreases significantly with the increase in aging temperature, while the elongation increases gradually.

2.3 Analysis

According to Figures 1 and 3, it can be seen that with the increase in aging temperature, the tensile strength of 15-5PH steel from different batches of the same manufacturer decreases gradually, while the absorbed energy and elongation increase gradually. Under the same aging regime, there is no significant difference in the room temperature and low-temperature tensile strength of 15-5PH steel from different batches of the same manufacturer, but there is a difference in the absorbed energy. Under the H485 regime, the low-temperature absorbed energy is the lowest, with an average of about 10J, while the low-temperature tensile strength is the highest, reaching 1468MPa. Under the H495 regime, the low-temperature absorbed energy and tensile strength do not differ much from those under the H485 regime. Under the H550 regime, the low-temperature absorbed energy increases significantly compared to the H485 regime, reaching 72J, while the low-temperature tensile strength is around 1200MPa. Under the H580 regime, the low-temperature absorbed energy increases slightly compared to the H550 regime. Under the H620 regime, the low-temperature absorbed energy increases significantly compared to the H550 regime, reaching 155J, but the low-temperature tensile strength is below 1110MPa.

Based on relevant research findings, from the perspective of matrix microstructure, the matrix microstructure under aging at 485°C does not differ much from the solution-treated state, and the martensitic strengthening effect remains significant. When the aging temperature exceeds 495°C, the spacing between martensite laths increases significantly. Starting from 550°C, with the increase in aging temperature, the martensitic matrix begins to decompose, and a large number of carbides precipitate. After aging at 620°C, more carbides continue to precipitate and grow along the grain boundaries and martensite lath boundaries, resulting in a decrease in matrix hardness. From the perspective of copper-rich precipitates, the precipitates are fine and dispersed at 485°C aging, and as the aging temperature increases, the number of Cu-rich phases decreases and their size increases, weakening the precipitation strengthening effect, leading to a gradual decrease in material strength and hardness. The significant increase in absorbed energy under the H550 and H620 regimes is mainly due to the formation of reverse-transformed austenite during the aging process. The volume fraction of austenite increases with the increase in aging temperature. When the aging temperature exceeds 550°C, the reverse transformation from martensite to austenite occurs, and the volume fraction of reverse-transformed austenite increases rapidly. At an aging temperature of 620°C, the Cu-rich phase grains grow, and the volume fraction of reverse-transformed austenite increases rapidly, causing solid solution softening and recovery of the matrix, thereby significantly improving the impact performance of the steel.

3 Conclusions

1) With the increase in aging temperature, the room temperature and low-temperature tensile strength of 15-5PH steel decrease gradually, while the absorbed energy and elongation increase gradually. Under the same aging regime, there is no significant difference in the low-temperature tensile strength of 15-5PH steel from different batches of the same manufacturer, but there is a certain difference in impact performance.

2) Under the same aging regime, the low-temperature absorbed energy of 15-5PH steel is significantly lower than that at room temperature. Under the H485 regime, the low-temperature absorbed energy is the lowest, and the low-temperature tensile strength is the highest. Under the H495 regime, the low-temperature absorbed energy and tensile strength do not differ much from those under the H485 regime. Under the H550 regime, the low-temperature absorbed energy increases significantly compared to the H485 regime, and the low-temperature tensile strength is around 1200MPa, with good comprehensive mechanical properties.