Effect of 18CrNiMo7-6 steel deep carburizing process on tissue properties

In the last decade or so, the high speed development of wind power generation, high speed railway, etc., European standard 18CrNiMo7-6 steel is widely used in the manufacture of wind power gearbox gears, large modulus gears, heavy load gears, etc.. As the gear modulus increases, the carburizing process requires an effective hardening layer depth of 3mm, or even 4mm or 5mm or more. For 18CrNiMo7-6 carburizing steel hardening layer depth of 3mm or more carburizing process, there have been different views in China, while Europe and the United States are using carburizing direct quenching process. Therefore, the 18CrNiMo7-6 steel hardening layer deeper than 3mm, using carburizing direct quenching and carburizing a quenching of two different processes, metallographic organization, mechanical properties research, for 18CrNiMo7-6 steel carburizing heat treatment to provide process test basis.

Test material and test method

The test 18CrNiMo7-6 steel is smelted by vacuum degassing in electric arc furnace, poured into ingots, opened by billet, forging dial length, and normalized, high-temperature tempering preheat treatment, made of φ30mm × 180mm round bar specimens, and then carburized. The chemical composition of the specimen is wC=0.18%, wSi=0.28%, wMn=0.70%, wCr=1.6%, wMo=0.29%, wNi=1.48%, wP=0.013%, wS=0.011%, H≤2×10-6, O≤20×10-6, and the rest is Fe.

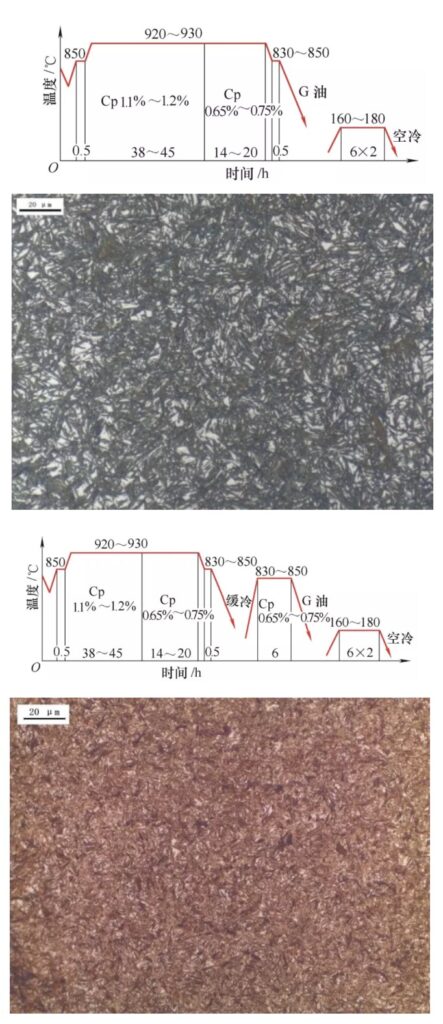

The φ30mm×180mm round bar specimen was carburized in Aichelin φ1600mm×2000mm well type controlled atmosphere carburizing furnace together with the gear, carburizing temperature was 920~930℃, carburizing strong carburizing period carbon potential was controlled at 1.1%~1.2%, strong carburizing time was 38~45h, diffusion period carbon potential was 0.65%~0.75%, diffusion time was 14~20h. Then the temperature is lowered with the furnace. Lowering the temperature to 830 ~ 850 ℃ insulation 0.5h out of the furnace. Two of the specimens directly into the 60 ℃ G oil quenching, quenching time of 30min; the other two specimens into the slow cooling furnace slowly cooled to room temperature, and then with the parts into the Aichelin multi-purpose furnace heating, heating temperature 830 ~ 850 ℃, carbon potential of 0.65% ~ 0.75%, insulation 6h, into the 60 ℃ G oil quenching, quenching time of 30min. 4 specimens are in 160 ~ 180 ℃ Tempered for 6h, out of the furnace air cooling. After carburizing and quenching, low temperature tempering according to GB/T25744-2010 “carburizing and quenching and tempering metallographic examination of steel parts” and GB/T9450-2005 “determination and verification of the depth of carburizing and quenching hardened layer of steel parts” for metallographic organization and effective hardening layer depth inspection. AI metallographic microscope to observe the organization, FM-700 semi-automatic micro hardness tester to check the depth of effective hardening layer, CMT5303 universal testing machine for tensile test, ZBC3302B impact tester for impact test.

Test results and discussion

1

Organizational properties of 18CrNiMo7-6 steel carburized and quenched directly

Test results: carburized layer organization as shown in Figure 2, C1 level, M4 level, residual A4 level, hardening layer depth HV1550: 3.84mm, surface hardness 60-61HRC; heart organization as shown in Figure 3, low carbon martensite; heart hardness 40HRC; grain size as shown in Figure 4; mechanical properties as shown in Table 1.

2

Organizational properties of 18CrNiMo7-6 steel carburized once quenched

Test results: carburizing layer organization as shown in Figure 6, C1 level, M3 level, residual A2 level, hardening layer depth HV1550: 3.90mm surface hardness 60-61HRC; heart organization as shown in Figure 7, low-carbon martensite; heart hardness 40HRC; grain size as shown in Figure 8; mechanical properties as shown in Table 2.

- Discussion

(1) Mechanical properties

18CrNiMo7-6 steel carburizing direct quenching plus low-temperature tempering and carburizing slow cooling reheating quenching and then low-temperature tempering, two processes after heat treatment of its tensile strength and yield strength are very high, tensile strength were 1229MPa, 1262MPa, yield strength were 1014MPa, 1048MPa, plasticity, toughness is very good, elongation were 9%, 9.5%, respectively. section shrinkage of 49%, 51%, impact absorbed energy of 49 J, 45 J. Two different carburizing and quenching methods, strength, plasticity, toughness indicators are very close, this is because the 18CrNiMo7-6 steel alloying element Cr in the alloy steel is mostly dissolved in the ferrite, so that the steel isothermal curve right shift, improve the strength and hardenability of steel, but also improve the hardness and wear resistance of steel. The alloying element Ni in equilibrium conditions almost completely dissolved in the ferrite, so that the steel isothermal curve right shift, and Ni steel in the heating of the grain is not easy to grow. the good role of Ni is to increase the content, can be appropriate to improve the strength at the same time, plasticity, toughness has a good impact, especially the low temperature impact toughness value is higher. The addition of Cr and Ni in steel at the same time, in addition to the strengthening effect of Cr, can also maintain the good role of Ni, so as to obtain high comprehensive mechanical properties. At the same time, due to the interaction of Cr and Ni, the hardenability of the steel is much improved, far beyond the role of separate elements. The addition of a small amount of Mo elements has the effect of refining the grain, so 18CrNiMo7-6 steel carburizing, quenching, low-temperature tempering after high strength, good plastic toughness.

(2) Organization

18CrNiMo7-6 steel carburizing direct quenching and low-temperature tempering and carburizing slow cooling reheating quenching and low-temperature tempering, two processes after heat treatment of the carburizing layer metallographic organization were martensite 4 and 3, residual austenite were 4 and 2, carbide are 1, the heart is low-carbon martensite, the actual grain size are 7 ~ 8. After carburizing direct quenching + low-temperature tempering, martensite and residual austenite level than carburizing, slow cooling, heating quenching + low-temperature tempering 1 and 2 levels higher, carbide and the heart are the same organization. Because, Ni and iron generation of infinite mutual solubility of the γ-phase region for austenite forming elements, Ni in steel can not be combined with carbon to form carbide; Cr, Mo and carbon can form carbide, is a medium carbide forming elements. 18CrNiMo7-6 steel in the carburizing slow cooling process, there will be Cr, Mo and other elements of carbide precipitation, so that the carbon content of austenite is reduced, in the re-heating quenching process, due to Cr, Mo and other elements of the carbide dissolution slower, austenite C, Cr, Mo content is reduced, so that the austenite martensite transformation start point is elevated, and thus the quenching and cooling organization is finer and less residual austenite. Therefore, carburizing direct quenching, low-temperature tempering than carburizing slow cooling, heating quenching, low-temperature tempering, the surface layer of high carbon martensite slightly coarser, slightly more residual austenite. ni steel in the heating of the grain is not easy to grow, while Mo also has the role of grain refinement, therefore, carburizing direct quenching and carburizing slow cooling and then heating quenching its grain size is basically the same, are 7 to 8 grade. Because of the good hardenability, the core are low-carbon martensite organization.

Conclusion

Through the 18CrNiMo7-6 steel deep carburizing direct quenching, low-temperature tempering and carburizing slow cooling reheating quenching, low-temperature tempering two process test research, the following conclusions.

(1) 18CrNiMo7-6 steel 930 ℃ carburizing, carburizing strong carburizing potential control 1.1% ~ 1.2%, time 40h, diffusion carbon potential 0.65% ~ 0.75%, time 15h, and then with the furnace cooling to 830 ℃, carbon potential 0.65% ~ 0.75%, holding 0.5h out of the furnace, at 60 ℃ G oil quenching, cooling 0.5h, and 160 ℃ × 6h tempering After, the carburizing layer organization C1 grade, M4 grade, A residual 4 grade, hardening layer depth HV1550: 3.84mm, surface hardness 60 ~ 61HRC, heart organization 1 grade, heart hardness 40HRC; grain size 7 ~ 8 grade; tensile strength: 1229MPa, yield strength: 1014MPa, elongation 9%, section shrinkage 49%, impact absorption energy 49J.

(2) 18CrNiMo7-6 steel 930 ℃ carburizing, carburizing strong carburizing potential control 1.1% ~ 1.2%, time 40h, diffusion carbon potential 0.65% ~ 0.75%, time 15h, then with the furnace cooling to 830 ℃, carbon potential 0.65% ~ 0.75%, insulation 0.5h out of the furnace slow cooling to room temperature, and then heated to 830 ℃, carbon potential 0.65% ~ 0.75%, insulation 6h, into 60 ℃ G oil quenching, and 160 ℃ × 6h after tempering, carburizing layer organization C1 level, M3 level, residual A2 level, hardening layer depth HV1550: 3.90mm surface hardness 60 ~ 61 HRC, heart organization 1 level, heart hardness 40HRC; grain size 7 ~ 8; tensile strength: 1262MPa, yield strength. 1048MPa, elongation 9.5%, section shrinkage 51%, impact absorption energy 45J.