Cold Stamping Mould Tool Steel

Fushun are main manufacturer of tool steel for cold stamping Mould.

What is Cold Stamping Mould?

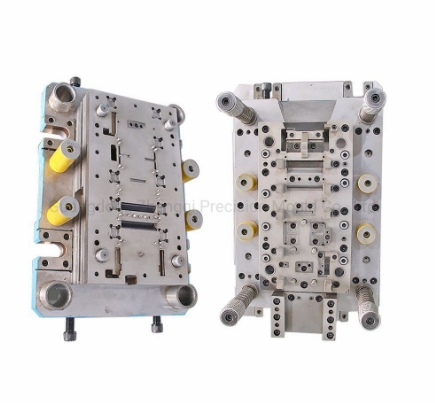

A cold stamping Mould, also known as a cold press Mould or cold forming Mould, is a specialized tool used in manufacturing processes to shape or cut metal sheets at room temperature without the application of heat. This tool is essential in metalworking operations such as punching, bending, drawing, and shaping metal parts to precise specifications.

The cold stamping Mould consists of two main parts: the punch (male component) and the Mould (female component). During the stamping process, a metal sheet or strip is placed between the punch and the Mould. When force is applied, typically by a mechanical or hydraulic press, the punch presses the metal into the Mould cavity, causing the metal to deform plastically and take on the desired shape or cut.

Applications of cold stamping Moulds are vast and include the production of components such as brackets, enclosures, connectors, and structural parts. The ability to produce durable and precise parts quickly makes cold stamping Moulds a fundamental tool in modern manufacturing.

Cold Stamping Mould Materials

| O2 | — | 1.2842 | — | 9Mn2V |

| O1 | SKS3 | 1.2510 | 95MnCr5 | 9CrWMn |

| — | SKS31 | — | CrWMn | |

| — | — | 1.2825 | 95MnWCr5 | MnCrWV |

| — | — | 1.2824 | 70MnMoCr8 | 7CrMn2Mo |

| — | — | — | Cr8Mo2SiV | |

| — | — | — | Cr4W2MoV | |

| — | — | — | 6Cr4W3Mo2VNb | |

| D3 | SKD1 | 1.2080 | X210Cr12 | Cr12 |

| — | SKD2 | X210CrW12 | Cr12W | |

| — | — | — | 7Cr7Mo2V2Si | |

| A2 | SKD12 | 1.2363 | X100CrMoV5 | Cr5Mo1V |

| D2 | SKD10 | 1.2379 | X153CrMoV12 | Cr12Mo1V1 |

| — | — | — | 8Cr3 | |

| H10 | — | 1.2365 | — | 4Cr3Mo3SiV |

| A8 | — | 1.2360 | X48CrMoV8-1-1 | 5Cr5WMnSi |

Chemical Composition of Cold Stamping Mould

| Grade | C | Si | Mn | Cr | W | Mo | V | Nb | Co |

| 9Mn2V | 0.85~0.95 | ≤0.40 | 1.70~2.00 | 0.10~0.25 | |||||

| 9CrWMn | 0.85~0.95 | ≤0.40 | 0.90~1.20 | 0.50~0.80 | 0.50~0.80 | 一 | |||

| CrWMn | 0.90~1.05 | ≤0.40 | 0.80~1.10 | 0.90~1.20 | 1.20~1.60 | ||||

| MnCrWV | 0.90~1.05 | 0.10~0.40 | 1.05~1.35 | 0.50~0.70 | 0.50~0.70 | 0.05~0.15 | |||

| 7CrMn2Mo | 0.65~0.75 | 0.10~0.50 | 1.80~2.50 | 0.90~1.20 | 0.90~1.40 | ||||

| Cr8Mo2SiV | C.95~1.03 | 0.80~1.20 | 0.20~0.50 | 7.80~8.30 | 2.00~2.80 | 0.25~0.40 | |||

| Cr4W2MoV | 1.12~1.25 | 0.40~0.70 | ≤0.40 | 3.50~4.00 | 1.90~2.60 | 0.80~1.20 | 0.80~1.10 | ||

| 6Cr4W3Mo2VNb | 0.60~0.70 | ≤0.40 | ≤0.40 | 3.80~4.40 | 2.50~3.50 | 1.80~2.50 | 0.80~1.20 | 0.20~0.35 | |

| Cr12 | 2.00~2.30 | ≤0.40 | ≤0.40 | 1.50~13.00 | |||||

| Cr12W | 2.00~2.30 | 0.10~0.40 | 0.30~0.60 | 11.00~13.00 | 0.60~0.80 | ||||

| 7Cr7Mo2V2Si | 0.68~0.78 | 0.70~1.20 | ≤0.40 | 6.50~7.50 | 1.90~2.30 | 1.80~2.20 | 一 | ||

| Cr5Mo1V | 0.95~1.05 | ≤0.50 | ≤1.00 | 4.75~5.50 | 0.90~1.40 | 0.15~0.50 | |||

| Cr12Mo1V1 | 1.40~1.60 | ≤0.60 | ≤0.50 | 11.00~13.00 | 0.70~1.20 | 0.50~1.10 | ≤1.00 | ||

| 8Cr3 | 0.75~0.85 | ≤0.40 | ≤0.40 | 3.20~3.80 | |||||

| 4Cr3Mo3SiV | 0.35~0.45 | 0.80~1.20 | 0.25~0.70 | 3.00~3.75 | 2.00~3.00 | 0.25~0.75 | |||

| 5Cr5WMnSi | 0.50~0.60 | 0.75~1.10 | 0.20~0.50 | 4.75~5.50 | 1.00~1.50 | 1.15~1.65 |

Properties of Cold Stamping Mould Steel

| Grade | Annealed HBW | Hardened HRC min. |

| 9Mn2V | ≤229 | 62 |

| 9CrWMn | 197~241 | 62 |

| CrWMn | 207~255 | 62 |

| MnCrWV | ≤255 | 62 |

| 7CrMn2Mo | ≤235 | 61 |

| Cr8Mo2SiV | ≤255 | 62 |

| Cr4W2MoV | ≤269 | 60 |

| 6Cr4W3Mo2VNb | ≤255 | 60 |

| Cr12 | 217~269 | 60 |

| Cr12W | ≤255 | 60 |

| 7Cr7Mo2V2Si | ≤255 | 60 |

| Cr5Mo1V | ≤255 | 60 |

| Cr12Mo1V1 | ≤255 | 59 |

| 8Cr3 | 207~255 | |

| 4Cr3Mo3SiV | ≤229 | |

| 5Cr5WMnSi | ≤248 |

Available Shapes from Fushun

*Round Bar

*Flat Bar

*Block

*Plate

Contact Information

Welcome your inquiry. We will send you a free quotation within 24 hours.