Cement Machinery Cast Steel Parts

We cast steel castings for cement machinery, including steel cast flanges, roller skins, large ring gears, vertical mill grinding discs, and other steel castings. The mechanical equipment involved includes vertical mills, cement trucks, and other types of cement machinery equipment. Our customized steel castings use high-quality raw materials, assisted by CAE simulation casting software for process design, strict control of the production process, and full-process inspection to ensure casting quality, providing customers with highly wear-resistant steel castings.

Materials:

Carbon Steel: 20Mn ZG30 25Mn ZG15(ZG200-400) ZG20 ZG35(ZG270-500) ZG45(ZG310-570) ZG25(ZG230-450) ZG55(ZG340-640) ZG275-485H ZG16Mn Q345B ZG30CrNiMo ZG30Mn Q255

Alloy Steel: 35SiMnCrMo SCMn3A 5CrMnMo SCSiMn2H ZG16Mn G20Mn5 ZG20CrNiMo Q345B ZG20MnCr R20CrMo ZG20MnMo CF3(304L) CF8(304) KmTBCr20Mo KmTBCr26

Product:

For more product, Please send email to info@fushunspecailsteel.com

ABOUT US:

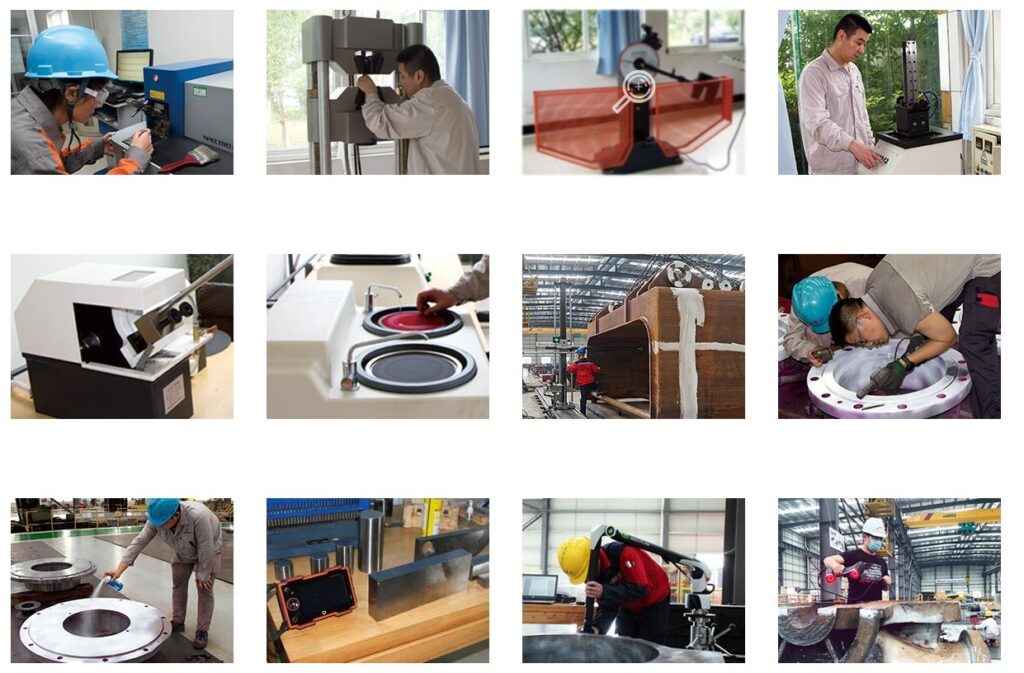

The casting production base has a workshop area of 18,000 square meters and a molding area of 10,000 square meters. Its annual designed production capacity is over 20,000 tons. It has three sets of medium-frequency furnaces of 3 tons, 2 tons, and 0.75 tons respectively. It is equipped with several energy-saving and environmentally-friendly lost wax casting and coated sand production lines, including automatic or semi-automatic production lines for core processes such as wax making, shell making, casting, and heat treatment. The machining base is equipped with advanced and complete CNC machining equipment, including over 50 vertical and horizontal machining centers, more than 60 CNC machine tools, more than 80 other machining equipment, including laser and plasma cutting machines, CNC bending machines, and welding robots. The machining factory has an independent management team and management mode from the casting factory. With rich supply chain management capabilities, in addition to precision cast steel components, it can also provide customers with precision machining of sand cast steel components, cast iron parts, forgings, profile machining components, and sheet metal parts. At the same time, the company also has many advanced testing equipment, such as spectrometers, metallographic microscopes, tensile testing machines, low-temperature impact testing machines, X-ray flaw detectors, magnetic particle flaw detectors, ultrasonic flaw detectors, three-coordinate measuring machines, and imaging measuring instruments. The above equipment can ensure that the company provides customers with high-standard precision castings that meet the comprehensive testing requirements for material physical and chemical properties, non-destructive defect testing, and high-precision geometric dimension inspection.