AISI 5160 Spring Steel

All About 5160 Steel (Properties, Strength, and Uses)

Alloy Steel 5160, also sold as AISI 5160, is a high carbon and chromium spring steel. It offers users outstanding toughness, a high level of ductility, and excellent fatigue resistance. Alloy Steel 5160 is in use in the automotive field in a number of different heavy spring applications, especially for leaf springs. It is important to note that Alloy Steel 5160 can be difficult to weld and machine and may require special procedures.

AISI 5160 steel, also known as 5160 spring steel, is a high carbon chromium alloy (maximum carbon content 0.61%, chromium content 0.9%). AISI SAE 5160 high carbon steel has excellent toughness, ductility and fatigue resistance and is commonly used in industrial applications as well as in the automotive sector for many different heavy duty spring applications, especially for leaf springs. In addition, 5160 carbon steel is also used to make knives and swords.

AISI 5160 Equivalent Grade

ASTM AISI SAE 5160 carbon steel equivalent to European EN (German DIN EN, British BSI, French NF…), Chinese GB and Japanese JIS standard.

| AISI 5160 steel equivalent | |||||||||

| US | Germany | China | Japan | ISO | |||||

| Standard | Grade (UNS) | Standard | Steel name (Steel number) | Standard | Grade | Standard | Grade | Standard | Grade |

| AISI SAE; ASTM A29/A29M; ASTM A322 |

5160 (G51600) | GB/T 1222 | 60CrMn | JIS G4801 | SUP9A | ||||

Continental Steel offers Alloy Steel 5160 in a number of different sizes and shapes including rounds, bars, and plates. All of our Steel Alloy 5160 meets or exceeds the leading industry standards like ASTM, SAE, and UNS.

Chemical Composition

The chemical composition of AISI 5160 alloy steel is listed in the following table.

| Element | Content (%) |

| Iron, Fe | 97.085 – 97.84 |

| Manganese, Mn | 0.750 – 1 |

| Chromium, Cr | 0.7 – 0.9 |

| Carbon, C | 0.560 – 0.640 |

| Phosphorous, P | ≤ 0.0350 |

| Silicon, Si | 0.150 – 0.3 |

| Sulfur, S | ≤ 0.04 |

Physical Properties

The following table shows the physical properties of AISI 5160 alloy steel.

| Properties | Metric | Imperial |

| Density | 7.85 g/cm3 | 0.284 lb/in³ |

Toughness Testing

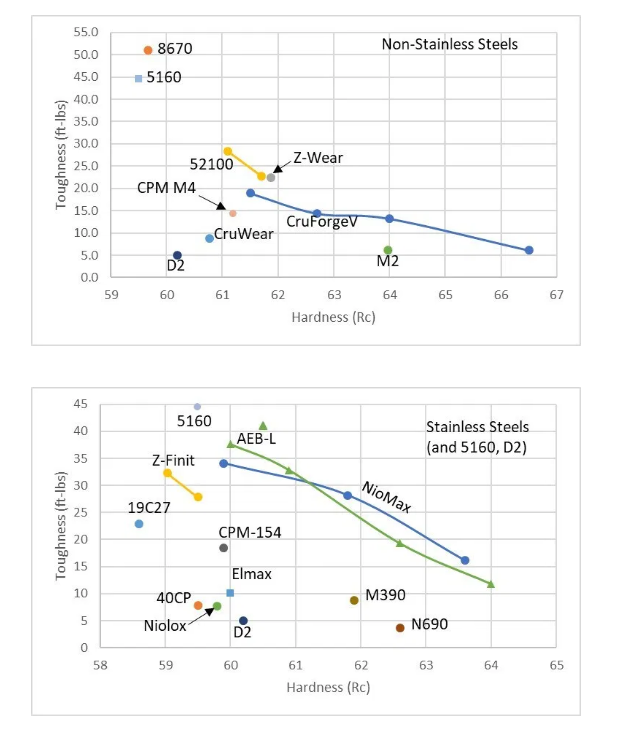

We used the same test procedure as has been used in all of our other toughness testing, with full specifications for the test samples on this page. They are 2.5 x 10 x 55 mm specimens without any notch (unnotched) and tested with a charpy impact tester. The toughness is measured by the energy required to fracture the specimen. You can lean about how charpy works in this article on toughness. Using this standard specimens allows us to compare the toughness of 5160 to all of the other knife steels we have tested.

Hardness

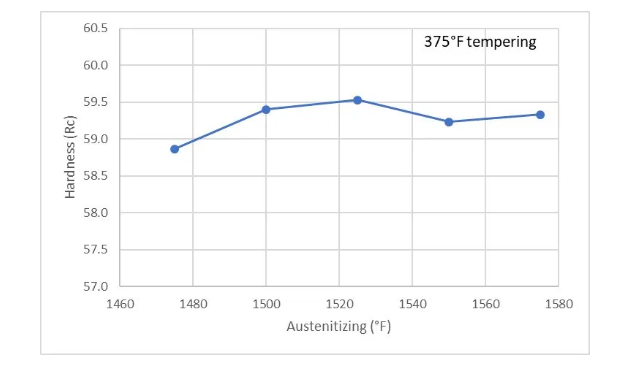

The lowest hardness was measured with the lowest austenitizing temperature (1475°F), as expected. However, hardness was relatively flat from 1500-1575°F, indicating that more carbide was dissolved by increasing from 1475 to 1500°F austenitizing temperature, but that there was not a significant change above that temperature.

Mechanical Properties

The mechanical properties of AISI 5160 alloy steel are outlined in the following table.

| Properties | Metric | Imperial |

| Tensile strength, ultimate | 724 MPa | 105000 psi |

| Tensile strength, yield | 275 MPa | 39900 psi |

| Modulus of elasticity | 190-210 GPa | 27557-30458 ksi |

| Bulk modulus (typical for steel) | 140 GPa | 20300 ksi |

| Shear modulus (typical for steels) | 80 GPa | 11600 ksi |

| Poissons ratio | 0.27 – 0.30 | 0.27-0.30 |

| Elongation at break (in 50mm) | 17.20% | 17.20% |

| Hardness, Brinell | 197 | 197 |

| Hardness, Knoop (converted from Brinell hardness) | 219 | 219 |

| Hardness, Rockwell B (converted from Brinell hardness) | 92 | 92 |

| Hardness, Rockwell C (converted from Brinell hardness, value below normal HRC range, for comparison purposes only) | 13 | 13 |

| Hardness, Vickers (converted from Brinell hardness) | 207 | 207 |

| Machinability (spheroidized annealed and cold drawn. Based on 100% machinability for AISI 1212 steel) | 55 | 55 |

Thermal Properties

The thermal properties of AISI 5160 alloy steel are outlined in the following table.

| Properties | Metric | Imperial |

| Thermal conductivity | 46.6 W/mK | 323 BTU in/hr.ft2. °F |

Physical Properties of 5160 Steel

It is important to understand the naming system for steel and its alloys, as the name reveals much about the composition of each alloy. Much like aluminum, steel is named using a four-digit identifier, but unlike aluminum, each number holds important information regarding the percentage of carbon and the associated alloying elements within the steel alloy. Also note that there are discontinuities between the AISI and SAE naming systems, but they are generally overlapping in terms of alloy names and will be treated as one naming entity in this article (AISI/SAE naming index).

The first digit of the steel alloy nomenclature represents the class of the steel alloy. In the case of 5160 aluminum, the 5 represents steel alloys that utilize chromium as the major alloying element. The second digit represents the concentration of the aforementioned alloying element; 5160 steel is therefore 1% chromium by mass. The last two digits represent the specific concentration of carbon, where they designate that the alloy is 0.XX % carbon. For 5160 steel, that means that the carbon concentration is 0.60% carbon, making it a medium to high carbon steel. Note that this is not a comprehensive analysis, and to be considered 5160 steel, the material must also achieve the concentration tolerances for the other elements as shown below: 0.75-1% Manganese 0.035% Phosphorus ≤ 0.15-0.3% Silicon ≤ 0.04% Sulfur

5160 steel is exceptionally tough and resilient. It sports a high level of resistance to fatigue, has high ductility, and has good spring qualities useful for applications where flexibility is desired. It is, therefore, part of the “spring steels”, which represent those alloys that are both flexible but have enough strength to return to their original shape post-deformation. While not easily welded or machined, 5160 steel can be heat-treated, annealed, and hot worked into shape. It has a density of 7.85 g/cm3 (0.284 lb/in3).

Fabrication and Heat Treatment

Machinability

Machining 5160 alloy steel is difficult in “as rolled” condition. Hence, the steel should be annealed before machining to obtain maximum speeds.

Welding

AISI 5160 alloy steel has poor welding property owing to its high chromium and carbon content. Either arc or gas welding methods can be used to weld the steel.

Heat Treatment

AISI 5160 alloy steel is generally hardened using oil. This steel is quenched at 829°C (1525°F) and tempered at temperatures ranging from 427 and 704°C (800 and 1300°F).

Forging

Forging of 5160 alloy steel is performed at temperatures between 1149 and 1204°C (2100 and 2200°F).

Annealing

AISI 5160 alloy steel is annealed at 788°C (1450°F) and then air cooled.

Applications of 5160 Steel

5160 steel is, as previously described, an ideal spring steel. Its hefty strength is often implemented in applications with smaller cross-sections under significant stress such as springs, fasteners, and leaf springs in automobile suspensions. It comes in bar and tube forms from suppliers and can be used to create exceptionally strong components, granted that you have the tools to process it. 5160 steel is also utilized when building scrapers and bumpers, and can make a great knife edge that is both durable and flexible. If ductility, toughness, and resilience are needed, consider asking your supplier about 5160 steel.