Corrosion-resistant Mould Tool Steel

Fushun are main manufacturer of tool steel for Corrosion-resistant Mould.

What is Corrosion-resistant Mould?

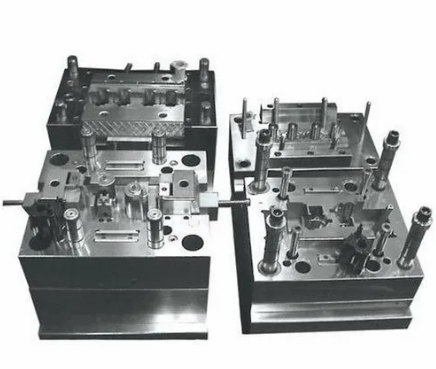

A corrosion-resistant mould is a specialized tooling engineered to withstand aggressive chemical environments and corrosive materials during the manufacturing process. These moulds are designed to maintain their structural integrity and surface quality when exposed to corrosive plastics, chemicals, acids, or materials that release corrosive gases during processing. Unlike standard moulds, these specialized tools incorporate advanced materials and protective treatments to prevent degradation and extend service life in hostile chemical environments.

The primary function of corrosion-resistant moulds is to process highly corrosive materials while maintaining consistent product quality and dimensional accuracy. These moulds are particularly crucial in manufacturing components for chemical processing, medical devices, and products involving aggressive compounds. The design incorporates features to minimize material trapping and stagnation points where corrosive substances might accumulate. Special attention is given to venting systems, cooling channels, and other features that might be exposed to corrosive agents, ensuring all components maintain their protective properties throughout the production cycle.

Corrosion-resistant moulds utilize materials with exceptional chemical resistance properties, typically including specialized stainless steel alloys and advanced surface treatments. These materials combine high corrosion resistance with the necessary mechanical properties required for moulding operations, such as wear resistance, thermal conductivity, and dimensional stability. The mould surfaces often receive additional protective treatments or coatings to enhance their corrosion resistance further while maintaining the required surface finish and release properties. These protective layers must maintain their effectiveness under repeated thermal cycling and mechanical stress while resisting chemical attack from the processed materials.

Corrosion-resistant Mould Materials

| ISO 4957 | Grade |

| 2Cr13 | |

| 4Cr13 | |

| — | 4Cr13NiVSi |

| 2Cr17Ni2 | |

| X38CrMo16 | 3Cr17Mo |

| — | 3Cr17NiMoV |

| 0Cr17Ni4Cu4Nb |

Chemical Composition of Corrosion-resistant Mould

| Grade | C | Si | Mn | Cr | Mo | Ni | V |

| 2Cr13 | 0.16~0.25 | ≤1.00 | ≤1.00 | 12.00~14.00 | ≤0.60 | ||

| 4Cr13 | 0.35~0.45 | ≤0.60 | ≤0.80 | 12.00~14.00 | ≤0.60 | ||

| 4Cr13NiVSi | 0.35~0.45 | 0.90~1.20 | 0.40~0.70 | 13.00~14.00 | 0.15~0.30 | 0.25~0.35 | |

| 2Cr17Ni2 | 0.12~0.22 | ≤1.00 | 150 | 15.00~17.00 | — | 1.50~2.50 | |

| 3Cr17Mo | 0.33~0.45 | ≤1.00 | ≤1.50 | 15.50~17.50 | 0.80~1.30 | ≤1.00 | |

| 3Cr17NiMoV | 0.32~0.40 | 0.30~0.60 | 0.60~0.80 | 16.00~18.00 | 1.00~1.30 | 0.60~1.00 | 0.15~0.35 |

| 0Cr17Ni4Cu4Nb | ≤0.07 | ≤1.00 | ≤1.00 | 15.00~17.00 | 3.00~5.00 | — |

Properties of Corrosion-resistant Mould Steel

| Grade | Annealed HBW |

| 2Cr13 | 220 |

| 4Cr13 | 235 |

| 4Cr13NiVSi | 235 |

| 2Cr17Ni2 | 285 |

| 3Cr17Mo | 285 |

| 3Cr17NiMoV | 285 |

Available Shapes from Fushun

*Round Bar

*Flat Bar

*Block

*Plate

Contact Information

Welcome your inquiry. We will send you a free quotation within 24 hours.