Mirror-finish Plastic Mould Tool Steel

Fushun are main manufacturer of tool steel for Mirror-finish Plastic Mould.

What is Mirror-finish Plastic Mould?

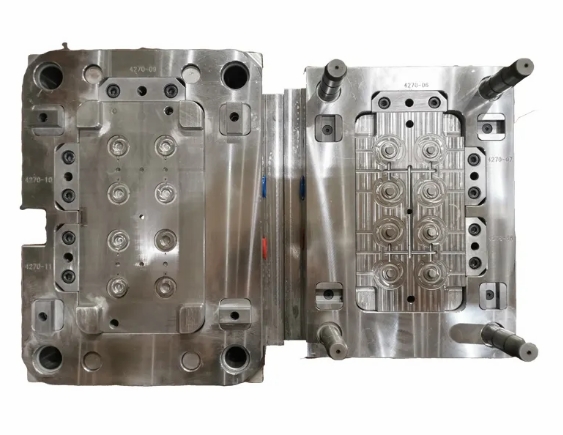

A mirror-finish plastic mold is a highly specialized tooling designed to produce plastic parts with an extremely smooth, reflective surface quality that resembles a mirror. These precision molds require exceptional surface finishing techniques, typically achieving surface roughness levels measured in nanometers. The mold construction demands meticulous attention to detail in both design and manufacturing, incorporating advanced polishing techniques and specific surface treatments to achieve and maintain the mirror-like finish required for high-end aesthetic products.

The primary purpose of mirror-finish molds is to produce plastic parts with perfect reflective surfaces without any visible defects such as flow lines, sink marks, or surface imperfections. These molds feature sophisticated temperature control systems to maintain consistent surface quality throughout the production cycle. The design must account for proper venting, optimized material flow patterns, and precise pressure distribution to prevent any surface defects that could compromise the mirror finish. Special attention is given to gate locations and cooling channel layouts to ensure uniform filling and cooling, preventing any surface irregularities.

The materials used in mirror-finish molds must possess specific characteristics to achieve and maintain the ultra-smooth surface finish. These molds require materials with exceptional hardness to resist wear and maintain the mirror finish over extended production runs, superior thermal conductivity for uniform cooling, and excellent polishability to achieve the required surface finish. The mold materials often undergo special heat treatments and surface enhancement processes to improve their wear resistance and surface stability. Additional surface treatments or coatings may be applied to enhance release properties and prevent any surface degradation that could affect the mirror finish of the molded parts. The mold design must also incorporate features to protect the highly polished surfaces during operation and maintenance.

Mirror-finish Plastic Mould Materials

| — | — | 1.2825 | 95MnWCr5 | MnCrWV |

| — | — | 1.2824 | 70MnMoCr8 | 7CrMn2Mo |

| H11 | SKD6 | 1.2343 | X37CrMoV5-1 | 4Cr5MoSiV |

| H13 | SKD61 | 1.2344 | X40CrMoV5-1 | 4Cr5MoSiV1 |

| — | — | 1.1191 | C45U | SM45 |

| — | — | — | SM50 | |

| — | — | SM55 | ||

| P20 | — | 1.2311 | 35CrMo7 | 3Cr2Mo |

| — | — | 40CrMnNiMo8-6-4 | 3Cr2MnNiMo | |

| — | — | — | 4Cr2Mn1MoS | |

| — | — | — | 8Cr2MnWMoVS | |

| — | — | — | 5CrNiMnMoVSCa | |

| — | — | —— | 2CrNiMoMnV | |

| — | — | — | 2CrNi3MoAl | |

| — | — | — | 1Ni3MnCuMoAl | |

| — | — | 2Cr13 | ||

| — | — | 4Cr13 | ||

| — | — | — | 4Cr13NiVSi | |

| — | 2Cr17Ni2 | |||

| — | X38CrMo16 | 3Cr17Mo |

Chemical Composition of Mirror-finish Plastic Mould

| Grade | C | Si | Mn | Cr | W | Mo | Ni | V |

| MnCrWV | 0.90~1.05 | 0.10~0.40 | 1.05~1.35 | 0.50~0.70 | 0.50~0.70 | 0.05~0.15 | ||

| 7CrMn2Mo | 0.65~0.75 | 0.10~0.50 | 1.80~2.50 | 0.90~1.20 | 0.90~1.40 | |||

| 4Cr5MoSiV | 0.33~0.43 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 一 | 1.10~1.60 | 0.30~0.60 | |

| 4Cr5MoSiV1 | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | 4.75~5.50 | 1.10~1.75 | 0.80~1.20 | ||

| SM45 | 0.42~0.48 | 0.17~0.37 | 0.50~0.80 | |||||

| SM50 | 0.47~0.53 | 0.17~0.37 | 0.50~0.80 | |||||

| SM55 | 0.52~0.58 | 0.17~0.37 | 0.50~0.80 | — | ||||

| 3Cr2Mo | 0.28~0..40 | 0.20~0.80 | 0.60~1.00 | 1.40~2.00 | 0.30~0.55 | 一 | ||

| 3Cr2MnNiMo | 0.32~0.40 | 0.20~0.40 | 1.10~1.50 | 1.70~2.00 | 0.25~0.40 | 0.85~1.15 | ||

| 4Cr2Mn1MoS | 0.35~0.45 | 0.30~0.50 | 1.40~1.60 | 1.80~2.00 | 0.15~0.25 | |||

| 8Cr2MnWMoVS | 0.75~0.85 | ≤0.40 | 1.30~1.70 | 2.30~2.60 | 0.70~1.10 | 0.50~0.80 | 0.10~0.25 | |

| 5CrNiMnMoVSCa | 0.50~0.60 | ≤0.45 | 0.80~1.20 | 0.80~1.20 | — | 0.30~0.60 | 0.80~1.20 | 0.15~0.30 |

| 2CrNiMoMnV | 0.24~0.30 | ≤0.30 | 1.40~1.60 | 1.25~1.45 | 0.45~0.60 | 0.80~1.20 | 0.10~020 | |

| 2CrNi3MoAl | 0.20~0.30 | 0.20~0.50 | 0.50~0.80 | 1.20~1.80 | 0.20~0.40 | 3.00~4.00 | ||

| 1Ni3MnCuMoAl | 0.10~0.20 | ≤0.45 | 1.40~2.00 | 0.20~0.50 | 2.90~3.40 | |||

| 2Cr13 | 0.16~0.25 | ≤1.00 | ≤1.00 | 12.00~14.00 | ≤0.60 | |||

| 4Cr13 | 0.35~0.45 | ≤0.60 | ≤0.80 | 12.00~14.00 | ≤0.60 | |||

| 4Cr13NiVSi | 0.35~0.45 | 0.90~1.20 | 0.40~0.70 | 13.00~14.00 | 0.15~0.30 | 0.25~0.35 | ||

| 2Cr17Ni2 | 0.12~0.22 | ≤1.00 | 150 | 15.00~17.00 | — | 1.50~2.50 | ||

| 3Cr17Mo | 0.33~0.45 | ≤1.00 | ≤1.50 | 15.50~17.50 | 0.80~1.30 | ≤1.00 |

Properties of Mirror-finish Plastic Mould Steel

| Grade | Annealed HBW |

| MnCrWV | ≤255 |

| 7CrMn2Mo | ≤235 |

| 4Cr5MoSiV | ≤229 |

| 4Cr5MoSiV1 | ≤229 |

| SM45 | 155~215 |

| SM50 | 165~225 |

| SM55 | 170~230 |

| 3Cr2Mo | 235 |

| 3Cr2MnNiMo | 235 |

| 4Cr2Mn1MoS | 235 |

| 8Cr2MnWMoVS | 235 |

| 5CrNiMnMoVSCa | 255 |

| 2CrNiMoMnV | 235 |

| 2CrNi3MoAl | |

| 1Ni3MnCuMoAl | |

| 2Cr13 | 220 |

| 4Cr13 | 235 |

| 4Cr13NiVSi | 235 |

| 2Cr17Ni2 | 285 |

| 3Cr17Mo | 285 |

Available Shapes from Fushun

*Round Bar

*Flat Bar

*Block

*Plate

Contact Information

Welcome your inquiry. We will send you a free quotation within 24 hours.