Rolling Edge Mould Tool Steel

Fushun are main manufacturer of tool steel for Rolling Edge Mould.

What is Rolling Edge Mould?

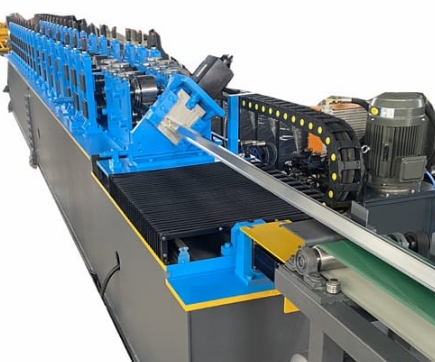

Rolling edge moulds (or Curling moulds) are specialized tooling systems designed for forming curved or rolled edges on sheet metal components. These moulds incorporate precisely engineered forming surfaces, guides, and pressure pads that work together to gradually form the material into the desired rolled edge profile. The design must carefully control material flow to prevent wrinkling or distortion during the rolling process.

The main function of rolling edge moulds is to create smooth, rounded edges on metal parts for both functional and aesthetic purposes. They are extensively used in manufacturing industries to produce components like automotive body panels, appliance housings, and metal containers. This process provides several benefits including enhanced part strength, improved safety by eliminating sharp edges, and better aesthetic appearance. Rolling edge moulds can handle various material thicknesses and achieve consistent edge quality in high-volume production environments.

The mould materials used in rolling edge applications contain specific alloying elements to provide optimal performance under repeated forming operations. Premium grade tool steels are used, incorporating combinations of chromium, tungsten, molybdenum, and vanadium to achieve the required mechanical properties. These materials provide excellent wear resistance while maintaining sufficient toughness to prevent surface damage or chipping. The microstructure features uniform carbide distribution that ensures long-term dimensional stability and wear resistance. Surface treatments are often applied to enhance durability and reduce friction during the rolling process, particularly important for maintaining smooth material flow and preventing surface marking on the finished parts.

Rolling Edge Mould Materials

| — | — | — | Cr8Mo2SiV | |

| A2 | SKD12 | 1.2363 | X100CrMoV5 | Cr5Mo1V |

| D2 | SKD10 | 1.2379 | X153CrMoV12 | Cr12Mo1V1 |

Chemical Composition of Rolling Edge Mould

| Grade | C | Si | Mn | Cr | Mo | V |

| Cr8Mo2SiV | C.95~1.03 | 0.80~1.20 | 0.20~0.50 | 7.80~8.30 | 2.00~2.80 | 0.25~0.40 |

| Cr5Mo1V | 0.95~1.05 | ≤0.50 | ≤1.00 | 4.75~5.50 | 0.90~1.40 | 0.15~0.50 |

| Cr12Mo1V1 | 1.40~1.60 | ≤0.60 | ≤0.50 | 11.00~13.00 | 0.70~1.20 | 0.50~1.10 |

Properties of Rolling Edge Mould Steel

| Grade | Annealed HBW | Hardened HRC min. |

| Cr8Mo2SiV | ≤255 | 62 |

| Cr5Mo1V | ≤255 | 60 |

| Cr12Mo1V1 | ≤255 | 59 |

Available Shapes from Fushun

*Round Bar

*Flat Bar

*Block

*Plate

Contact Information

Welcome your inquiry. We will send you a free quotation within 24 hours.