The control of inclusions during the electroslag remelting (ESR) process of duplex stainless steel F55 is as follows:

Duplex stainless steel F55 has high strength, good formability and weldability, excellent resistance to localized corrosion and stress corrosion cracking caused by chlorides. Typical applications include petrochemicals, fertilizer industries, flue gas desulfurization (FGD) installations in power plants, seawater, and hot seawater environments. Inclusions, especially brittle inclusions, in the steel can adversely affect the plasticity during hot working and the fatigue and corrosion resistance properties of the product. Therefore, it is necessary to strictly control the types and quantities of inclusions in the steel. High-end F55 products are typically produced using ESR, which yields a good solidification structure and purity, resulting in superior product performance.

Factors affecting inclusion removal:

1.1 Original inclusions in the consumable electrode

During the ESR process, the removal of inclusions is influenced by the types and quantities of inclusions present in the consumable electrode. The types and quantities of inclusions in the consumable electrode are mainly related to the final deoxidation practice used in the electrode refining process. Geng Xin and others conducted experimental research on the effect of final deoxidation methods on inclusion removal. The data indicated that consumable electrodes produced using Al for final deoxidation had a lower inclusion removal rate after ESR because the deoxidation product Al2O3 has a high melting point and small particle size, making it difficult for the slag to absorb it. Additionally, Al2O3 reduces the interfacial tension between inclusions and liquid metal, which is also unfavorable for inclusion separation from the molten metal. When the consumable electrode was deoxidized with a complex deoxidant AMS and Ca-Si, the inclusion content in the steel dropped significantly after ESR due to the lower melting point and larger size of the complex deoxidation products, which are easier to float up and be removed by the slag.

1.2 Composition of the slag

Impurities such as FeO, Cr2O3, MnO, and SiO2 in the slag, being variable-valence metal oxides, can cause oxidation of active elements like Si, Mn, Al, Ti in the steel. Therefore, during the ESR stage, the slag needs to be deoxidized to minimize the presence of unstable oxides in the slag. Zhou Deguang, Wang Changsheng, and others improved the type and distribution of inclusions in bearing steel using complex deoxidants and acid slags in their research. They found that consumable electrodes produced using complex deoxidation, after being remelted with acid slags, resulted in inclusions primarily composed of sulfides and silicates, significantly improving the fatigue life of the steel.

1.3 Electrode melting speed

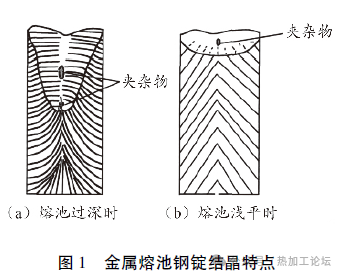

Figure 1 illustrates the relationship between the rating of oxide inclusions in ball bearing steel and the remelting speed.

As shown in Figure 1, the higher the electrode melting speed, the deeper the metal melt pool, making it more difficult for inclusions to float up, corresponding to a higher rating of inclusions in the steel.

1.4 Atmosphere during ESR

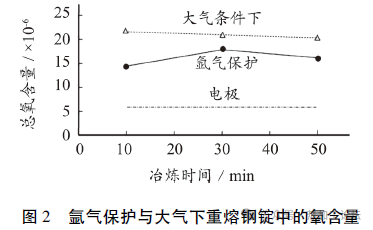

Wang Changsheng and others verified the effect of atmosphere conditions on refining efficiency during ESR by comparing the oxygen content in the ingots remelted under argon protection and atmospheric conditions, as shown in Figure 2. It can be seen that compared to atmospheric ESR, the use of atmosphere protection can significantly reduce the increase in oxygen content in the molten metal.

2 Preparation of F55 electrodes:

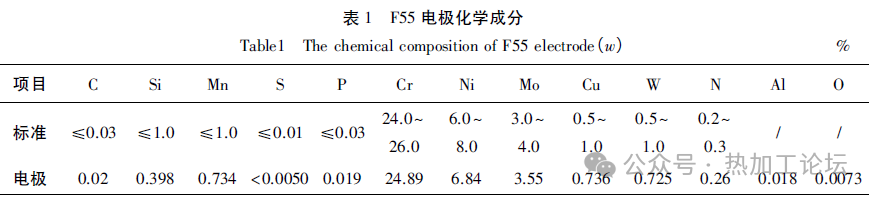

A company uses a “3-ton medium-frequency induction furnace + 3-ton AOD” process to smelt consumable electrodes of duplex stainless steel F55. During the AOD refining stage of F55 electrodes, after blowing is completed, pre-reduction is performed with 15-20 kg/t of Si-Al complex deoxidant, followed by alloy adjustments with minor chromium, molybdenum iron, electrolytic nickel, etc. Before tapping, Al is added to the steel at a rate of 3-5 kg/t for final reduction, and 1 kg/t of Si-Ca alloy is added to the ladle to modify Al2O3 inclusions in the steel. The tapping temperature is (1600±20) °C, the molten metal is held still for 5-8 minutes, and the pouring temperature is (1550±10) °C. The specifications and quantities of the cast electrodes are: Φ160 mm × 3000 mm, 2 pieces, each weighing 0.5 tons; Φ300 mm × 2900 mm, 1 piece, weighing 1.5 tons. The chemical composition of the F55 electrodes is shown in Table 1.

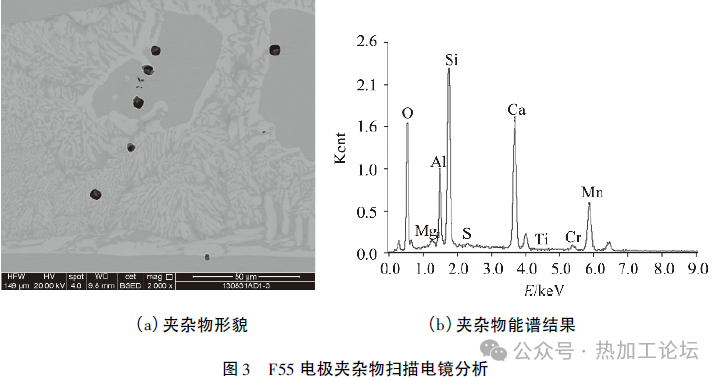

To determine the type of inclusions in the electrodes, SEM detection was performed on samples taken from the body of the electrodes. The morphology of the inclusions is shown in Fig. 3(a). The EDS results in Fig. 3(b) indicate that the main type of inclusion in the electrode is a low-melting-point complex inclusion of CaO-Al2O3-SiO2-MgO. These complex inclusions are remnants from the casting process that did not have time to float up, and they have a low melting point, making them easy to remove during ESR by floating into the slag.

3 ESR trial scheme for F55:

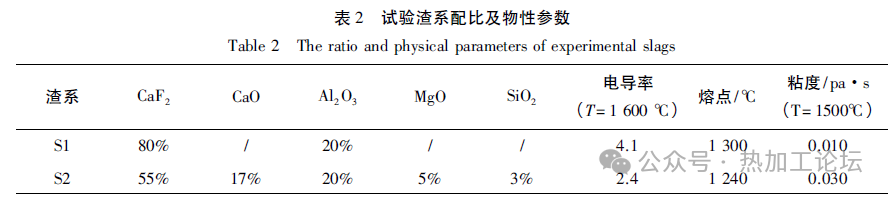

Before ESR, the electrode surface was thoroughly ground to remove the oxide layer, slag, and other impurities, and then baked at 600°C for 5 hours. After baking, the electrodes were welded to dummy electrodes and hoisted to the ESR position. The ESR equipment used was a 0.5 ton and 1.5 ton fixed ESR furnace with mold sizes of Φ260 mm and Φ460 mm, respectively. The slag system ratios and physical parameters used in the trial are shown in Table 2. Slag system S1 is commonly used for fixed ESR furnaces, while slag system S2 includes an appropriate amount of MgO to form a semi-solidified film on the surface of the slag pool, preventing oxygen uptake by the molten metal and reducing the transmission of variable-valence oxides from the slag to the metal melt pool. Adding an appropriate amount of SiO2 to the slag system is inspired by the role of acidic slag, where SiO2 in the slag combines with Al2O3 inclusions in the steel to form low-melting-point, easily removable silico-aluminous complex inclusions. Before ESR, the slag materials were baked at 850°C for more than 6 hours, and CaO was added in the form of pre-melted slag.

After baking the slag materials, they were added to the molds, and solid-state slag was used to start the arc and melt the slag, taking approximately 30-40 minutes. The trial schemes are shown in Table 3. Since the slag usually contains a small amount of unstable oxides like Fe2O3 and MnO, enhancing the slag’s oxidizing nature, the slag must be deoxidized. The amounts of deoxidants used in this remelting trial are shown in Table 4.

Experimental results and analysis:

4.1 Chemical composition analysis

The chemical composition of the F55 ESR ingots is shown in Table 5. It can be seen that when the five-component slag system (S2) was used for remelting trials, the oxygen content in the steel was the lowest, whereas when the two-component slag system (S1) was used for remelting trials, the oxygen content in the steel decreased very little or even slightly increased.

The oxygen content in the steel is linearly related to the residual aluminum content, as shown in Fig. 4. The higher the residual aluminum content, the higher the oxygen content in the steel.

Since the main type of inclusions in the base material of the F55 electrode is a complex inclusion of CaO-Al2O3-SiO2-MgO, and the main inclusions in the steel after ESR are Al2O3, it suggests that Al2O3 inclusions do not originate from the electrode, confirming that Al2O3 comes from ESR deoxidation products. To solve the problem of increased oxygen content in the ingot after ESR, the following conditions need to be met: (1) The temperature of the metal melt pool cannot be too high, and a lower melting speed should be adopted; (2) The viscosity of the slag system should be higher, or atmosphere protection should be used to reduce gas absorption; (3) The slag system used for ESR should have a strong adsorption capacity for Al2O3 inclusions. In Trials 3 and 4, complex deoxidants Si-Ca were used to diffuse deoxidize the slag, forming silicate compounds that can combine with Al2O3 inclusions in the steel to form low-melting-point CaO-Al2O3-SiO2 complex inclusions, which are easily removed by the slag, thereby reducing the number of Al2O3 inclusions in the steel and lowering the oxygen content in the steel. Because the five-component slag system S2 has a lower melting point, better fluidity, and is inherently acidic, it has a stronger binding ability with Al2O3 inclusions, hence Trial 4, which used the five-component slag system, resulted in lower oxygen content and inclusion content in the steel after remelting.

4.2 Inclusion analysis

To further verify the relationship between residual aluminum content and oxygen content, SEM analysis was performed on the inclusions in the F55 ESR ingots, as shown in Fig. 5. The EDS results indicate that the main type of inclusions in the four trials of the ESR ingots was Al2O3, and the higher the oxygen content, the greater the quantity of Al2O3 inclusions. Thus, it is believed that Al2O3 inclusions directly lead to an increase in oxygen content in the F55 ESR ingots.

4.3 Forging trial

The surface quality of the F55 ESR ingots was good, and they were forged on a 5-ton hydraulic hammer. The forging heating temperature was 1200-1220°C, with a holding time of 3-4 hours, and the final forging temperature was 980°C. The size of the forging billet was Φ515/Φ265 mm × 145 mm, with no visible cracks on the surface of the forgings, and ultrasonic testing was passed.

Conclusion:

(1) During the ESR process of duplex stainless steel F55, the higher the melting speed of the electrode, the deeper the metal melt pool, making it less favorable for the removal of Al2O3 inclusions from the steel. A lower remelting speed is recommended.

(2) When using a two-component slag system for ESR, if only Al is used for deoxidation, the slag system has a weaker adsorption capacity for Al2O3 inclusions, resulting in an unobvious deoxidation and inclusion removal effect. Using a complex deoxidant Si-Ca to deoxidize and modify the slag is beneficial for the removal of Al2O3 inclusions in the steel. The five-component slag system has a stronger adsorption capacity for Al2O3 compared to the two-component slag system, achieving a better inclusion removal effect.