The effect of aging treatment on the room temperature and low-temperature mechanical properties of 15-5PH stainless steel is as follows:

15-5PH stainless steel (05Cr15Ni5Cu4Nb) is a martensitic precipitation-hardening stainless steel. Due to its high strength, good toughness, and corrosion resistance, it is widely used in load-bearing structural components in fields such as aerospace, naval vessels, ordnance, and oil machinery. The strength and toughness of 15-5PH stainless steel mainly come from the addition of Cu elements, which precipitate fine and dispersed ε-Cu phase and a small amount of carbides during aging treatment after solution annealing, thus achieving hardening effects and obtaining high strength, high toughness, and good corrosion resistance. Gao Xiaoting et al. studied the effect of solution annealing on the microstructure of 15-5PH stainless steel and found that extending the holding time of solution annealing can reduce the content of ferrite. Hua Xiaozhen et al.’s research shows that increasing the solution annealing temperature and holding time of 15-5PH stainless steel will lower the Ms point and increase the size of the original austenite grains. Liu Zhenbao et al. studied the effect of carbon content on the microstructure and mechanical properties of 15-5PH sheet metal. The results showed that with an increase in carbon content, the content of reverse transformation austenite in the steel increased, causing a certain degree of decrease in the strength of the steel. Qiu Zhan’an et al.’s research shows that as the solution annealing temperature increases, the room temperature tensile strength and hardness of 15-5PH stainless steel also increase, but its ductility and toughness decrease. When the solution annealing temperature is around 1040°C, 15-5PH stainless steel achieves the best combination of plasticity and toughness. Relevant studies have shown that as the aging treatment temperature of 15-5PH stainless steel increases and the holding time extends, its strength decreases while the impact energy absorption increases, mainly due to the gradual increase in the volume fraction of austenite. Li Wei et al. studied the effect of heat treatment on the machining performance of 15-5PH stainless steel, and the results showed that heat treatment has little effect on the dimensional change rate of 15-5PH steel parts, making it suitable for precision machining.

Currently, research on 15-5PH stainless steel primarily focuses on the effect of heat treatment on microstructure and room temperature mechanical properties, but there are no reports regarding the low-temperature mechanical properties of 15-5PH stainless steel. This article mainly studies the effect of different holding times (1, 2, and 4 hours) during aging treatment at 480°C on the room temperature and -50°C low-temperature mechanical properties of 15-5PH precipitation-hardened stainless steel, providing a theoretical basis for its engineering application under low-temperature environments and the optimization of related heat treatment procedures.

1. Experimental Materials and Methods

1.1 Test Materials

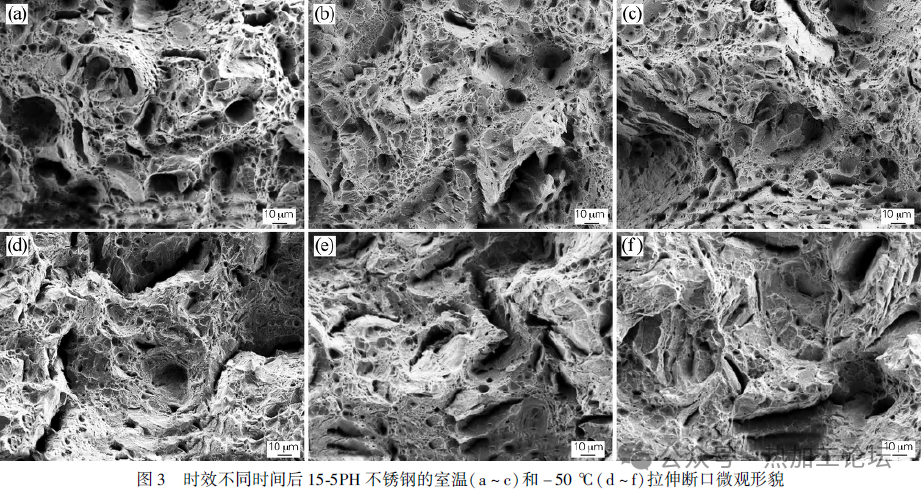

15-5PH stainless steel ingots were smelted using vacuum induction plus vacuum consumable electrode methods. The chemical composition is shown in Table 1. The ingot was heated to 1200°C for forging, then after forging and rolling, a bar with a diameter of ϕ35mm was obtained. After annealing, longitudinal specimens were cut from the end of the bar using a grinding wheel saw for physical and chemical property testing and analysis.

1.2 Testing Methods

Longitudinal tensile specimens, longitudinal impact specimens, and transverse metallographic specimens were cut from the specimen sections. These specimens were first heated to 1040°C in a muffle furnace and held for 1 hour for solution annealing, followed by air cooling to room temperature. Then they underwent aging treatment at 480°C for 1, 2, and 4 hours respectively, followed by air cooling to room temperature after the holding period ended. Tensile tests and U-notch impact tests were performed according to GB/T228.1-2021 ‘Metal materials—Tensile test—Part 1: Method of test at room temperature’, GB/T228.3-2019 ‘Metal materials—Tensile test—Part 3: Method of test at low temperatures’, and GB/T229-2020 ‘Metal materials—Charpy pendulum impact test method’. Microstructure analysis was performed using a ZEISS Axio Imager A 2m optical microscope. The macroscopic fracture morphology was observed using a ZEISS Discovery 2.0 stereomicroscope. The microscopic fracture morphology of tensile and impact tests was observed using a ZEISS ULtr55 scanning electron microscope. The austenite content in the specimens was tested using a D8 Advance X-ray diffractometer (Cu target).

2. Experimental Results and Analysis

2.1 Performance Analysis

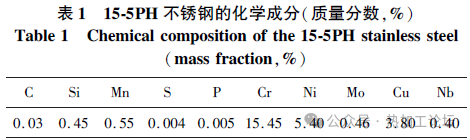

The results of the mechanical property testing of 15-5PH stainless steel after solution annealing at 1040°C and aging treatments for different times at 480°C are shown in Figure 1. As the aging holding time extended, there was relatively little change in the tensile properties of the material. From Figures 1(a, b), it can be seen that as the aging holding time increased from 1 hour to 4 hours, the room temperature tensile strength and yield strength of 15-5PH stainless steel fluctuated between 1332~1342 MPa and 1238~1252 MPa, respectively. At -50°C, the tensile strength and yield strength fluctuated between 1392~1416 MPa and 1262~1317 MPa, respectively. The elongation and reduction of area at room temperature fluctuated between 13.00%~13.75% and 56.0%~58.5%, respectively. The elongation and reduction of area at -50°C fluctuated between 12.75%~15.75% and 55%~59%, respectively. As the aging holding time extended, the absorbed impact energy showed an upward trend. From Figure 1(c), it can be seen that as the aging holding time increased from 1 hour to 4 hours, the absorbed impact energy at room temperature increased from 122J to 129J, and at -50°C, it increased from 31.5J to 77.5J.

2.2 Fracture Analysis

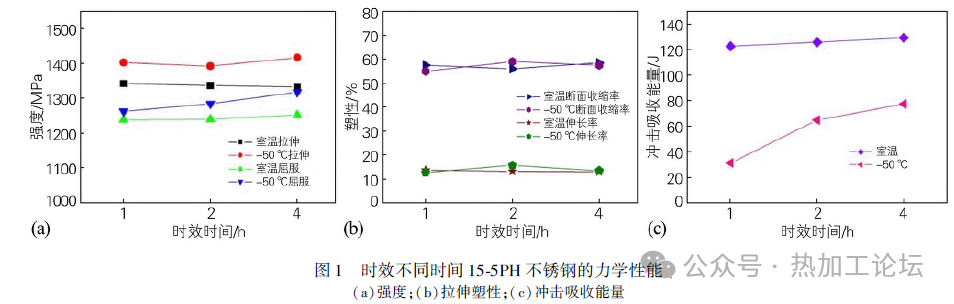

The fracture morphology of specimens aged for different times was observed using a scanning electron microscope, and the results are shown in Figures 2 and 3. It can be seen that the fracture morphology of the tensile specimens at room temperature and -50°C after different aging times all exhibit a cup-and-cone shape. Among them, the shear lip region occupies a large proportion of the room temperature tensile fracture, the center fiber zone is oval-shaped, and the surface is relatively rough, with observable larger, deeper dimples without obvious radiated zones (see Figures 2(a~c)). Compared to the room temperature tensile specimens, the shear lip region occupies a smaller proportion of the -50°C tensile fracture, the center fiber zone is circular, and the surface is also relatively rough, with radiated secondary cracks observable originating from the center fiber zone (see Figures 2(d~f)).

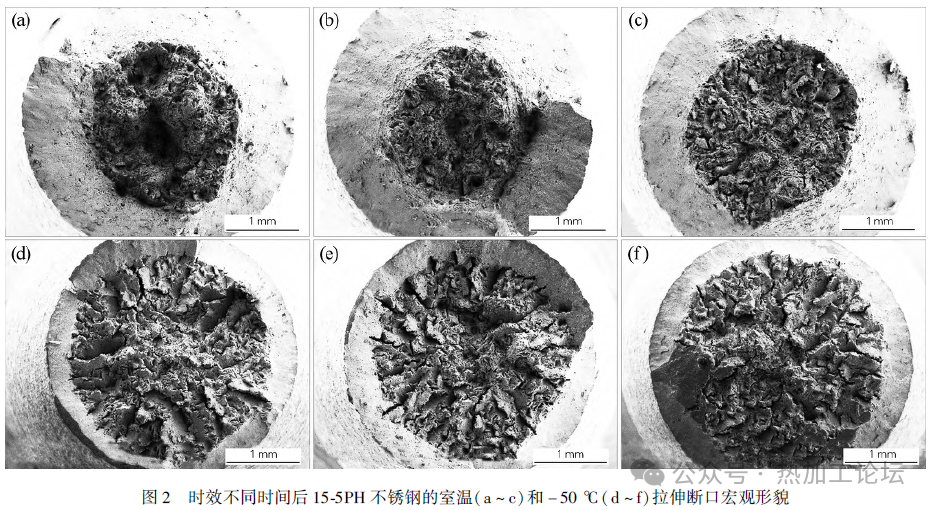

The microscopic fracture morphology of the fiber zones of tensile specimens at room temperature and -50°C after different aging times are basically similar, as shown in Figure 3.

The macroscopic fracture morphology of the impact specimens after different aging times is shown in Figure 4. By comparison, it can be seen that the room temperature impact fractures have an obvious shear lip, and the fiber zone adjacent to the specimen notch forms an arc-shaped protrusion along the crack propagation direction. With the extension of aging holding time, the area of the fiber zone is roughly the same (see Figures 4(a~c)). The -50°C impact fractures are relatively flat, with no shear lip observable. Compared to the room temperature impact specimens, the fiber zone adjacent to the specimen notch is smaller and relatively flat, and with the extension of aging holding time, the area of the fiber zone of the -50°C impact fractures shows a clear increasing trend (see Figures 4(d~f)).

The microscopic fracture morphology of the impact specimens after different aging times was observed using SEM, as shown in Figure 5. Comparing these, it can be seen that the width and morphology of the fiber zones on the impact fractures at room temperature and -50°C have significant differences. The fiber zones of the room temperature impact specimens form an arc-shaped protrusion along the crack propagation direction towards the radiated zone, with a clearly undulating morphology within the region, and obvious cracking phenomena can be observed along the peaks and valleys. There is a slight difference in the width of the fiber zones of the specimens aged for different times at room temperature. As the aging holding time increased from 1 hour to 4 hours, the maximum width of the fiber zone increased from approximately 1800 μm to approximately 2100 μm (see Figures 5(a~c)). The morphology of the fiber zones of the -50°C impact fractures differs significantly from those of the room temperature impact fractures, appearing as strip-like parallel to the processing notch of the specimen. At -50°C, the fiber zone morphology of the specimens aged for 1 hour is flat, with a width of about 500 μm; the fiber zone of the specimens aged for 2 hours has undulations parallel to the processing notch direction, with the entire fiber zone being about 750 μm wide; the fiber zone of the specimens aged for 4 hours has multiple undulations parallel to the processing notch direction, with partial cracking observable along the ridges and valleys, and the entire fiber zone is about 900 μm wide (see Figures 5(d~f)).

Further magnification of the fiber zones and radiated zones of the above specimens shows that the fiber zones mainly consist of dense shallow dimple morphologies (see Figure 6), while the radiated zones are undulating with multidirectional small cleavage plane morphologies (see Figure 7).

2.3 Microstructure Analysis

The microstructure of 15-5PH stainless steel after different aging times is shown in Figure 8. From Figure 8, it can be seen that the matrix microstructure of the specimens is all fine and uniform tempered martensitic laths, with an average grain size of about 30 μm.

XRD was used to analyze the phases of the metallographic specimens, as shown in Figure 9. The results show that in the specimens aged for 1 hour at 480°C, apart from the martensitic α’ phase, almost no austenitic γ phase could be observed. After aging for 2 hours, a weak γ phase (111) crystal plane diffraction peak could be observed in the specimens, in addition to the martensitic α’ phase. After aging for 4 hours, a weak γ phase (111) and (200) crystal plane diffraction peaks could be observed in the specimens, in addition to the martensitic α’ phase. This indicates that with the extension of aging holding time, the content of reverse transformation austenite in the specimens increases. Quantitative analysis shows that the content of the austenitic γ phase in the specimens aged for 2 hours is approximately 3.3%, while the content of the austenitic γ phase in the specimens aged for 4 hours is approximately 4.9%.

From the above results, it can be seen that under the premise of fixed solution annealing and aging temperatures, the extension of aging holding time has a significant effect on the -50°C low-temperature impact properties of 15-5PH stainless steel, but has an insignificant effect on the -50°C low-temperature tensile properties and room temperature mechanical properties. Relevant literature indicates that after aging treatments at 480 to 620°C, 15-5PH stainless steel mainly consists of tempered martensitic α’ and reverse transformation austenite formed through diffusion transformations. However, when aging treatments are performed at 480°C and lower temperatures, it is difficult to detect the presence of reverse transformation austenite through XRD analysis. Only after long-term aging can a small amount of reverse transformation austenite be observed. Research by Liu Zhenbao et al. shows that the content of reverse transformation austenite in stainless steel plays an important role in improving the room temperature plasticity and toughness. Other studies have shown that the formation of reverse transformation austenite during aging treatments can significantly improve the low-temperature toughness of martensitic aging stainless steels. Therefore, specimens aged for 4 hours at 480°C have higher low-temperature impact properties due to their higher content of reverse transformation austenite, and larger undulations can be observed when analyzing the fiber zone width. When the aging time is only 1 hour, almost no reverse transformation austenite can be observed in the specimens, resulting in the lowest low-temperature impact properties and the smallest and flattest fiber zone morphology.

Conclusions:

1) For 15-5PH precipitation-hardened stainless steel subjected to solution annealing at 1040°C for 1 hour, aging treatments at 480°C for different holding times (1, 2, and 4 hours) have an insignificant effect on the room temperature and -50°C low-temperature tensile properties. As the aging holding time increased from 1 hour to 4 hours, the room temperature tensile strength and yield strength of 15-5PH stainless steel fluctuated between 1332~1342 MPa and 1238~1252 MPa, respectively. At -50°C, the tensile strength and yield strength fluctuated between 1392~1416 MPa and 1262~1317 MPa, respectively. The elongation and reduction of area at room temperature fluctuated between 13.00%~13.75% and 56.0%~58.5%, respectively. The elongation and reduction of area at -50°C fluctuated between 12.75%~15.75% and 55%~59%, respectively.

2) For 15-5PH precipitation-hardened stainless steel subjected to aging treatments at 480°C, the absorbed impact energy showed an upward trend with the extension of aging holding time. As the aging holding time increased from 1 hour to 4 hours, the absorbed impact energy at room temperature increased from 122J to 129J, and at -50°C, it increased from 31.5J to 77.5J.

3) For 15-5PH precipitation-hardened stainless steel subjected to aging treatments at 480°C, the longer the aging holding time, the higher the content of reverse transformation austenite in the steel, leading to better low-temperature impact properties.