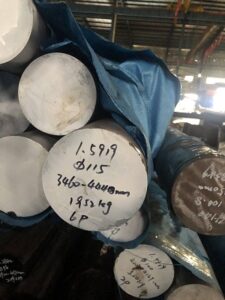

1.5919, 15CrNi6, Alloy Steel

1.5919 Alloyed case hardening steel for highly strained parts and good toughness at core tensile strength of 900 – 1200 N/mm². Driving bevel gears, crown wheels, gears, shafts, bolts for automotive and gear components.

| Chemical

composition: (Typical analysis in %) |

C | Si | Mn | Cr | Ni | other |

| 0,15 | 0,25 | 0,50 | 1,55 | 1,55 | (Pb) |

| Hot forming and

heat treatment: |

Forging or hot rolling:

Normalising: Soft annealing: Carburising: Core hardening: Intermediate annealing: Case hardening: Tempering: |

1100 – 850°C

850 – 880°C/air 650 – 700°C/furnace 880 – 980°C 830 – 870°C/oil 630 – 650°C 780 – 820°C/oil 150 – 200°C |