1.2740 Hot Work Tool Steel

The material 1.2740 belongs to the material group “Tool Steels For Hot Work”. We also have the chemical analysis of 1.2740 available for you below. Material “1.2740” is made of Carbon, Chrome, Manganese, Molybdenum, Nickel, Phosphorus, Silicon, Sulfur and Vanadium. In future we plan to add mechanical properties of “1.2740”, complete data-sheets as well as a PDF-Overview for you to download. For now you can easyily inquire this steel-material without obligation by using our contact-form. For correct determination of the shipping costs we need your shipping address. Please keep in mind that a detailed calculation can take a few days, depending on quantity, shipping-adress as well as forms and materials. We will contact you in any case.

Cutting:

Precision cutting to standard dimensions

Custom cutting according to client specifications

Surface Grinding/Polishing:

Thickness tolerance: -0 to +0.1mm

Flatness: 0.01/100mm

Surface roughness: Ra ≤1.6 or Rz ≤6.3

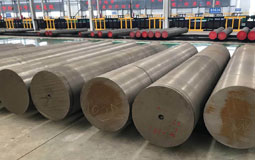

The high quality Germany DIN 1.2740 material is one of the more steel grades we supply, Hot working alloy tool steel. 1.2740 is our main production grade, which has been approved by customers in many countries since its initial production, including our 1.2740 round bars, flat bar, forgings, fasteners, tubes, wires, strips, sheets & Plates, as well as a variety of profiles, professional high precision auto-lathe processing manufacturer of clinching fasteners, axes, standoffs, screws, studs, nuts, bolt, OEM parts and special shaped turning partsthe state of delivery includes quenched and tempered, annealed, machined semi-finished products, we also have strict management of the packaging, to avoid material damage from transportation. We are the best supplier of 1.2740 materials, and we are willing to develop together with customers from all over the world.

Also includes 1.2740 steel material norm, chemical composition, mechanical properties, datasheet, 1.2740 equivalent, heat treatment and temperature process of 1.2740, The peak hardness can be achieved, Contains all of the specification, welding properties, let us in 1.2740 this steel grade have a more comprehensive understanding,

Introduction Hot Working Tool Steel(1.2740)

Hot working steels are a group of steel used to cut or shape material at high temperatures. H-group tool steels were developed for strength and hardness during prolonged exposure to elevated temperatures. These tool steels are low carbon and moderate to high alloy that provide good hot hardness and toughness and fair wear resistance due to a substantial amount of carbide. H1 to H19 are based on a chromium content of 5%; H20 to H39 are based on a tungsten content of 9-18% and a chromium content of 3–4%; H40 to H59 are molybdenum based.

The hot working tool steel consists of three kinds of hammer forging die, hot extrusion die and die casting die. As mentioned earlier, the main feature of the working condition of the hot die is to contact with the hot metal, which is the main difference from the working conditions of the cold working die.

Characteristic (1.2740)

The metal in the surface of the mold cavity is heated. Usually, when the hammer forging dies work, the surface temperature of the die cavity can reach 300~400 degrees or more, and the hot extrusion die can reach 500 or 800 degrees or more. The temperature of the die cavity is related to the type and pouring temperature of the die casting material. As for the die casting black metal, the mold cavity temperature can reach more than 1000 degrees centigrade. This high temperature can reduce the hardness and strength of the cavity surface significantly, and easily occur during the use. Therefore, the basic performance requirement of hot die steel is high thermoplastic resistance, including high temperature hardness, high temperature strength and high thermoplastic resistance. In fact, it reflects the high tempering stability of steel. Therefore, the first way to alloying hot die steel can be found, that is, adding Cr, W, Si. and other alloy elements can improve the tempering stability of the steel.

Chemical composition (wt.%)

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | V(%) |

| 0.24-0.32 | 0.30-0.50 | 0.20-0.40 | Max 0.030 | Max 0.030 | 0.60-0.90 | 2.30-2.60 | 0.50-0.70 | 0.25-0.32 |

Mechanical Properties

| Rp0.2 (MPa) | Rm (MPa) | Impact KV (J) |

Elongation A (%) |

A Z (%) | Delivery | Hardness HB |

| 737 (≥) | 223 (≥) | 11 | 13 | 12 | Solution & Aging, Ann, Ausaging, Q+T | 112 |