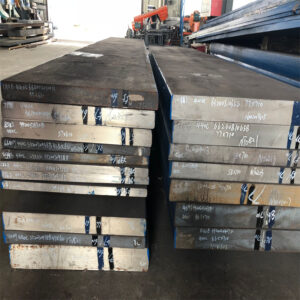

1.2746, 45NiCrMoV16-6, Cold Work Tool Steel

Chemical Composition : %

| C | Si | Mn | P | S | Cr | Mo | Ni | V |

| 0,41-0,49 | 0,15-0,35 | 0,60-0,80 | ≤ 0,025 | ≤ 0,020 | 1,40-1,60 | 0,73-0,85 | 3,80-4,20 | 0,45-0,55 |

Cutting:

Precision cutting to standard dimensions

Custom cutting according to client specifications

Surface Grinding/Polishing:

Thickness tolerance: -0 to +0.1mm

Flatness: 0.01/100mm

Surface roughness: Ra ≤1.6 or Rz ≤6.3

Description:

special cold work tool steel, air or oil hardenable with highest toughness.

Applications:

forging tools, dies of all sorts, shapes and sizes, hot forging and pressing tools for steel and

metal. Moulds, bushings, piercers, etc.

Phisical properties (avarages values ) at ambient temperature:

Modulos of elasticity [103xN/mm2].: 210

Density [g/cm3]: 7,86

Soft annealing:

Heat to 610-850°C, cool slowly in furnace. This will produce a maximum

Brinell hardness of 295.

Stress Relieving:

Stress relieving to remove machining stresses should be carried out by heating to approx. 650°C, holding for 1-2 hours atheat, followed by air cooling.

This operation is performed to reduce distortion during heat treatment.

Hardening:

Harden from a temperature of 880-910°C followed by air or oil quenching or warm bath quenching 180-220°C. Hardness after quenching is 56 HRC.