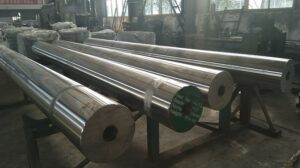

P750 HS Nonmagnetic Steel

We produce P750 HS non-mag material Steel Bars and Non Magnetic Hollow Bars.

1. CHEMICAL COMPOSITION

P750 HS is a high pitting corrosion resistant nonmagnetic, austenitic Cr-Ni-N-steel, specifically developed for oilfield applications.

| C | Mn | Cr | Mo | N | Ni |

| max. 0,03 | 1,50 – 3,00 | 26,50 – 29,50 | 2,00 – 4,00 | min. 0,20 | 28,00 – 31,50 |

2. MECHANICAL PROPERTIES

Following mechanical properties (tested at room temperature) are achieved by a special cold-working process over the full length of the collar:

| TEXT | OD | KSI | N/MM |

| Yield Strength (min.) 0,2%-offset method: | OD max. 91/2“ | 160 ksi | 1104 N/mm² |

| Tensile Strength (min.): | 165 ksi | 1139 N/mm² | |

| Elongation (min.): | 10% | 10% | |

| Reduction of area (min.): | 50% | 50% | |

| Impact energy (min.): | 80 ft.lb | 110 J | |

| Endurance Strength / N=10⁵ (min.): | ± 80 ksi | ± 550 N/mm² | |

| Hardness Brinell: (min.): | 300-420 HB | 300-420 HB |

3. MAGNETIC PROPERTIES

Relative permeability: ≤ 1,001.

4. CORROSION RESISTANCE

- Transgranular SCC:Prevented by special surface treatments (Hammer peening, roller burnishing, shot peening).

- Intergranular SCC:The occurrence of material sensitization is prevented by quenching after warm forging. Each collar is tested according to ASTM A 262, Pact.A and E, last edition.

- Pitting Corrosion:Due to a high chromium-, nickel- and nitrogen contents a excellent resistance to pitting corrosion comparable to nickel base alloys is given.

5. NON-DESTRUCTIVE TESTING

- Magnetic inspection:Drill collars are 100% tested by a proprietary probe-testing process. Magnetic permeability of each collar is certified with the printout of probe-testing.

- Ultrasonic inspection:Each collar is ultrasonically inspected over 100% of the volume according to ASTM E 114, last edition as a minimum level.