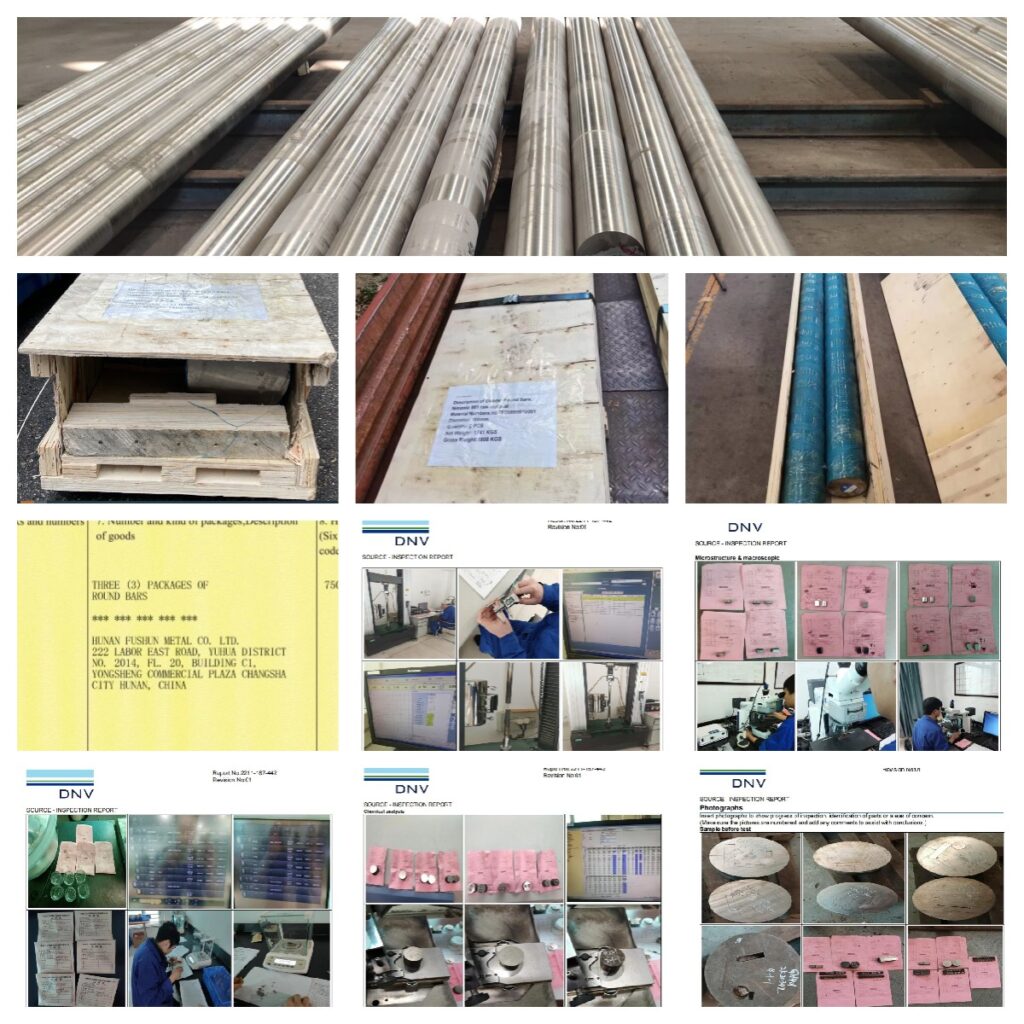

Excellent quality to win orders! 901 Nickel Alloy Bar For Swiss Clients.

Order picture show

Client’s dimension:

| Commodities Name | Steel Grade | Dimensions | Quantity | ||

| Diameter | Length | ||||

| (mm) | (mm) | PCS | KGS | ||

| NICKEL ALLOY BARS

|

UNS N09901 | 150 | 3788 | 1 | 539 |

| 150 | 3423 | 1 | 486 | ||

| 200 | 3296 | 1 | 840 | ||

| 200 | 3523 | 1 | 901 | ||

| 150 | 200 | 1 | 27 | ||

| 200 | 200 | 3 | 147 | ||

| TOTAL | 8 | 2940 | |||

Client’s application:

The alloy is used for components in aircraft and gas turbines, such as turbine rotors, compressor discs, hubs and shafts, with a maximum service temperature around 1100ºF (595ºC).

Heat-treated:

1.Solution Treatment: 1975/2025°F (1080/1107°C), hold 2 hours at heat, and water quench.

2.Stabiliztion Treatment: 1400/1475°F (760/802°C), hold 2 to 4 hrs, and air cool.

3.Precipitation Hardening Treatment:1300/1375°F (704/746°C), hold for 24 hours, and air cool.

What is 901?

Incoloy 901 Alloy nickel-iron-chromium alloy containing titanium and aluminum for precipitation hardening and molybdenum for solid-solution strengthening. The alloy has high yield strength and creep resistance at temperatures to about 1110°F (600°C). A substantial iron content enables the alloy to combine high strength with good forging characteristics. Used in gas turbines for discs and shafts. Standard products form is round.

Your also know as:

Inconel® incoloy 901, NIMONIC® 901, Alloy 901, AISI 681, AISI 682, PWA 1002, PWA 1003, SPS M259, UNS N90901, AMS 5660, AMS 5661, B50A305B, Werkstoff 2.4662, DIN 1.4898,

Is 901 weldability?

Alloy 901 can be welded by the inert-gas-arc method. It is difficult to weld. All welding should be done in the solution treated condition. Cold worked parts should be re-solution treated before welding. A re-solution treatment is recommended after welding before stabilizing and aging.