High Speed Steel Circular Saw Blades

Chemical component

Supplying size*stocking and accept nonstandard size

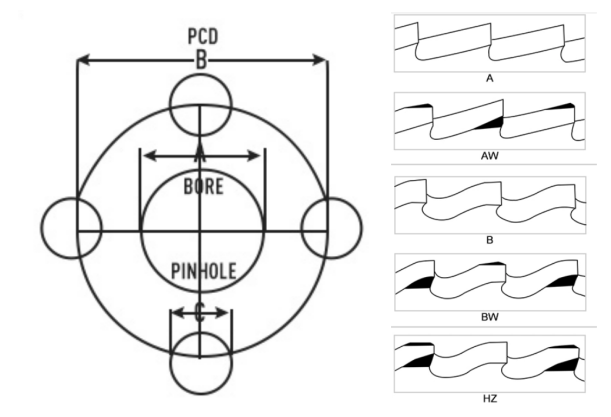

*four pin hole, Six pin hole, or client’s request

SurfaceNitride coating (black)Nitride treatment forms a protective layer of Fe304 on the surface of the saw blade through surface treatment, which effectively improves the anti-wear properties of the saw blade and increases its service life for cutting general materials.

SurfaceNitride coating (black)Nitride treatment forms a protective layer of Fe304 on the surface of the saw blade through surface treatment, which effectively improves the anti-wear properties of the saw blade and increases its service life for cutting general materials.

Aluminized titanium nitride coating (color)This is a new multi-layer anti-wear coating, recommended for cutting materials with relatively high cutting speed and feed depth and cutting tensile strength over 800N/mm and stainless steel, and for use in particularly harsh working conditions such as dry cutting.

Titanium nitride coating (gold)The main purpose of this coating is to make the saw blade more resistant to cutting, and for general material cutting, its excellent performance can effectively increase the cutting speed and reduce the working loss.

Brown CoatingThis is a high performance PVD coating for severe abrasive wear cutting conditions. Suitable for dry 800n/mm or more high tensile strength materials and stainless steel. Especially for high speed cutting materials and feeds. Coating thickness 0.003mm.

Super A coatingThe unique Super A coating is mainly suitable for cutting speed higher feed rate conditions, especially for cutting stainless steel and other hard materials, mainly used for dry automobile and motorcycle manufacturing.

Industrial titanium coating (gold color)This is a professional PVD coating resistant to adhesive wear, corrosion and oxidation. It is highly recommended for cutting copper and titanium and has achieved excellent results in cutting off bar, bronze and light alloy operations.

Rose Gold CoatingWith superior high temperature hardness, wear resistance and oxidation resistance, it is especially suitable for high speed milling and dry cutting of various difficult machining materials (Ti, Ai, Ni, Mg alloy, stainless steel).

HSS saw blade also called cold saw, which is designed to cut metal material to transfer the heat generated by cutting to the chips created by the circular saw blade, allowing both the blade and material being cut to remain cool. High speed steel (HSS) saw blade is a kind of blade composed of a certain amount of carbon (C), tungsten (W), molybdenum (Mo), chromium (Cr), vanadium (V), etc. High speed steel blanks, the semi-finished products have high hardness after cutting, forging, annealing, quenching and grinding procedures. Due to the high cutting temperature, however, hardness is still not significantly reduced when it reaches 600 °C or above. The cutting speed can reach more than 60 meters per minute. That the reasons why named high speed steel (HSS) saw blade.

APPLICATIONWhat Materials Do HSS Saw Blade Cut ?HSS circular saw blades are ideal for sawing or cutting off a wide variety of sizes and shapes such as extrusions, tubes, pipes, sheets, plates and some bar stock, including:1 medium to high tensile carbon steel2 sticky materials3 thin walled steel tubes & profiles4 non-alloy tool steel, etc.

CHARACTERISTICSThe Popularity of HSS Saw BladesHSS saw blade can be sharpened with blade sharpening machine or CNC grind machine, which will improve its production efficiency and reduce costs.The popularity of HSS saw blades is increasing because of the technological advancements in grinding machines.HSS saw blades consistently produce the lowest cost per cut among all sawing methods.

APPLICABLE MACHINERYWidely Applied on Pipe Cutting MachinesHigh-speed steel saw blades are widely applied on below machinery:automatic hydraulic pipe cutting machinesemi-automatic hydraulic pipe cutting machinemetal circular saw machinepipe cutting machinepipe processing machinerysawing machinemilling machine, etc.

| Grade | C | W | V | Mo | Cr | Co |

| HSS-DMo5 M2 DIN 1.3343 | 0.83-0.88 | 5.6-6.0 | 1.75-1.95 | 4.6-5.0 | 3.8-4.4 | / |

| HSS-Co5% M35 1.3243 | 0.83-0.88 | 5.6-6.0 | 1.75-1.95 | 4.6-5.0 | 3.8-4.4 | 4.6-4.8 |

| HSS-Co2% M42 | 0.9-1.0 | 5.6-6.0 | 1.75-2.25 | 4.6-5.0 | 3.8-4.4 | 1.8-2.2 |

| Diameter | Thickness | Inner Bore | Step | Weight | ||

| mm | mm | mm | mm | kg | ||

| 200 | 1.2/1.6/2.0 | 32 | 90 | 0.3/0.4/0.5 | ||

| 225 | 1.2/1.6/2.0 | 32 | 90 | 0.3/0.5/0.6 | ||

| 250 | 1.2/1.6/2.0/2.5 | 32/40 | 90 | 0.5/0.6/0.7/0.9 | ||

| 275 | 1.2/1.6/2.0/2.5 | 32/40 | 90 | 0.7/0.9/1.1/1.2 | ||

| 300 | 1.2/1.6/2.0/2.5/3.0 | 32/40 | 100 | 0.6/0.8/1.0/1.3/1.6 | ||

| 315 | 1.6/2.0/2.5/3.0 | 32/40 | 100 | 0.8/1.1/1.4/1.7 | ||

| 325 | 1.6/2.0/2.5/3.0 | 32/40 | 100 | 0.9/1.2/1.5/1.8 | ||

| 350 | 2.0/2.5/3.0 | 32/40/50 | 120 | 1.5/1.8/2.0 | ||

| 400 | 2.0/2.5/3.0 | 40/50 | 120 | 2.0/2.5/3.0 | ||

| Inner Bore(mm) | Pin Hole(mm) | |||||

| 32 | 2/8.5/45 2/11/63 | |||||

| 2/8.5/45 2/9/50 2/12/64 | ||||||

| 2/8.5/45 | ||||||

| 40 | 2/8.5/55 4/12/64 | |||||

| 2/15/80 4/12/64 | ||||||

| 2/15/80 2/15/100 4/12/64 | ||||||

| 50 | 4/15/80 | |||||

| 4/18/100 | ||||||

| 4/15/85 |