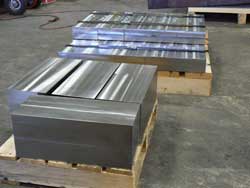

H13 1.2344 SKD61 Tool Steel Vacuum Hardened Machined Block

H13 Tool Steel Introduction:

H13 steel is the most popular and most versatile, hot work mould steel, providing a good balance of toughness, heat check resistance, and high temperature strength, in addition to moderate wear resistance. H13 steel can resist softening to 550°C and has good resistance to heat checking.

We can provide more services:

1、Hardening and tempering

2、Vacuum heat treatment

3、Polished bright surface

4、Milling bright surface

5、CNC machine

6、Deep drilling

7、Cut into small pieces

8、Make it closer to the mold

Welcome to inquiry price from drawing

Cutting:

Precision cutting to standard dimensions

Custom cutting according to client specifications

Surface Grinding/Polishing:

Thickness tolerance: -0 to +0.1mm

Flatness: 0.01/100mm

Surface roughness: Ra ≤1.6 or Rz ≤6.3

H13 Tool Steel Applications:

H13 steel is an air hardening, 5% chromium die steel, which is an excellent choice for a wide range of hot work and cold work applications. Typical applications include die casting dies for aluminium, magnesium and zinc, extrusion dies for aluminium and brass, liners, mandrels, pressure pads, followers, bolsters, die cases, die holders and adaptor rings for copper and brass extrusion. H13 steel is used to produce hot stamping and press forge dies, split hot heading dies, gripper dies, hot punching, piercing and trimming tools. Other applications include plastic moulds, shear blades for hot work and hot swaging dies.

H13 Tool Steel General Properties:

H13 steel is characterized by

Good resistance to abrasion at both low and high temperatures.

High level of toughness and ductility Uniform and high level of machinability and polishability.

Good high-temperature strength and resistance to thermal fatigue.

Excellent through-hardening properties.

Very limited distortion during hardening.

Good machinability.

H13 Tool Steel Quality Standard:

ASTM A681 Standard Specification for Tool Steel

H13 Tool Steel All Grades Comparison:

| AS 1239 | ASTM A 681 | BS 4659 | BS EN ISO 4957 | JIS G 4404 | Werkstoff |

| H13A | H13/UNS T20813 | BH13 | X40CrMoV 5-1 | SKD 61 | 1.2344/X40CrMoV5-1 |

H13 Tool Steel Chemical Composition(%):

| Steel Grade | C | Si | Mn | P | S | Cr | Mo | V |

| H13 | 0.32-0.45 | 0.90-1.25 | 0.20-0.60 | 0.030 max | 0.030 max | 4.75-5.50 | 1.10-1.75 | 0.80-1.25 |

| DIN1.2344 | 0.35-0.42 | 0.80-1.20 | 0.25-0.50 | 0.030 max | 0.030 max | 4.80-5.50 | 1.20-1.50 | 0.80-1.15 |

| SKD61 | 0.35-0.42 | 0.80-1.20 | 0.25-0.50 | 0.030 max | 0.020 max | 4.80-5.50 | 1.00-1.50 | 0.80-1.15 |

H13 Tool Steel Heat-Treatment Option

1 Annealed:

2 Vacuum heat treatment : Quenched and Tempered

| Type | Preheat Temperature,°F (°C) | Salt Bath | Controlled Atmosphere Furnaces | Austenitizing Time (minutes) | Quench Medium | Tempering Temperature,°F (°C) | Minimum Hardness,RC |

| H13 | 1450 (788) | 1825 (996) | 1850 (1010) | 5-15 | Air | 1025 (552) | 52 |

H13 Tool Steel Smelting Option

ESR Electro Slag Remelting Or other smelting, please contact with us.

H13 Tool Steel Delivery Option

Package: Plastic material bundled ; wooden case ; wooden/steel pallet ; client’s requirement

Payment: Paypal / TT

Transport: DHL / FEDEX / UPS / EMS

H13 Tool Steel Surface condition

Usual surface conditions are

- a) the hot-rolled or forged condition (= as hot worked),

- b) the machined (ground, polished, turned, peeled or milled) condition, and

- c) the cold-reduced condition.

Unless otherwise agreed at the time of enquiry and order, the products shall be delivered in the surface condition hot worked.

H13 Tool Steel Surface quality

1 All products shall have a smooth surface finish appropriate to the manufacturing processes applied. Minor surface imperfections, which also may occur under normal manufacturing conditions, such as prints originating from rolled-in scale, are not to be regarded as defects.

Bars shall be delivered with surface class A in accordance with ISO 9443 unless otherwise agreed at the time of enquiry and order. Plates shall be delivered in accordance with ISO 7788 unless otherwise agreed at the time of enquiry and order.

2 Ground, polished or finished-machined products shall be free from surface imperfections and surface decarburization.

3 Hot-rolled, forged, cold-drawn or rough-machined products shall be ordered with sufficient material to be removed from all surfaces by machining or grinding to allow for

- a) surface decarburization, and

- b) surface imperfections.

Providing no International Standard for the machining allowances of tool steels is available, the allowances shall be agreed at the time of enquiry and order.

H13 Tool Steel Mill’s test certificate:

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.