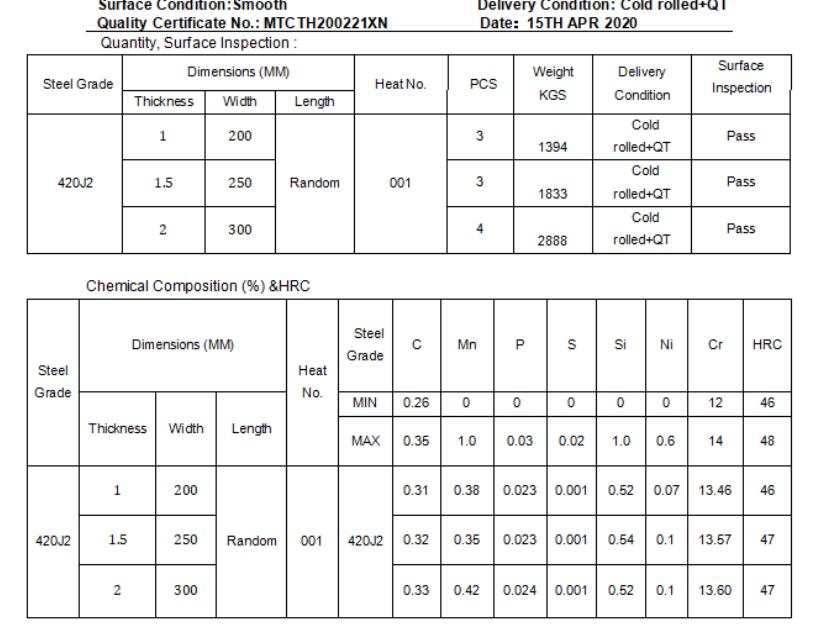

We, Fushun Metal, delivered a order of SUS420J2 cold rolled +quenched+tempered+polished stainless steel strip for Egypt clients. Thickness from 1.0 to 2.0 mm and Width from 200 to 300mm. We controlled the tolerance of thickness in the gap of -0, +0.025~+0.045mm and surface roughness Ra0.8μm.

Here is introduction of SUS420J2:

1.Application:

Cutlery, Nozzle valve seats, valves and liner scales

2.Grade comparison:

| JIS | EN DIN | ASTM AISI |

| SUS420J2 | 1.4028 | 420 |

3.Chemical composition (%):

| C | Si | Mn | P | S | Cr |

| 0.26-0.40 | 1.00max | 1.00max | 0.040max | 0.030max | 12.00-14.00 |

How we produce this order:

First, we purchased good quality raw material, hot rolled annealed pickled coil, from TISCO:

Second, the SUS420J2 coil is reduced to final thickness by cold rolling process, or with annealing at some intermediate thickness to facilitate further cold reduction or to obtain mechanical properties desired in the finished product.

Then, the 420 stainless strip transported to quench and temper lines. quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness.Depending on the temperature and composition of the steel, it can be hardened or softened. To make steel harder, it must be heated to very high temperatures.

After that, this quenched and tempered stainless steel strip had done the polished process for reach client’s request of Ra 0.8 μm.

Finally, we coiled the strip’s inside diameter according to client’s machine size. After inspection quality, we painted the anti-corrosion oil on the strip’s surface and set on wooden or steel plate for convenience loading on client side.

The test result of this order:

We, Fushun Metal, also can produce several color surface stainless steel strip with 0.1-3.0mm thickness and 10-350mm width. Our produced steel strip have better property on straightness, stability, surface etc.