Quenching

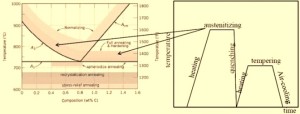

Quenching is the process for making material harder. The metal is heated to a specific temperature and rapidly cooled (quenched) in a bath of water, brine, oil, or air to increase its hardness.

One drawback of using this method by itself is that the metal becomes brittle. This treatment is therefore typically followed by a tempering process which is a heating process at another lower specific temperature to stress relieve the material and minimize the brittleness problem. The temperature chosen for the tempering process directly impacts the hardness of the work piece . The higher the temperature in the tempering process, the lower the hardness.

We can supply follows heat treatment services:

Normalizing, Annealing, Quenching, Tempering, Carburizing, Nitriding, High-frequency surface hardening and other processing services.

And we can strictly enforce the national standards.

And we have follows heating equipment:

Pit furnace: Dia1300mm max, Length9500mm max.

Salt bath furnace: Length1900mm max, Width1600mm max, Height900mm max.

Trolley furnace: Legth15000mm max, Width6000mm max, Height6000mm max.

Tunnel type continuous reheating furnace:dia30mm-dia250mm

Induction quenching line: dia15mm-dia120mm

Normalizing cooling fan can be used in combination of wind capacity air-cooled systems.