Normalizing

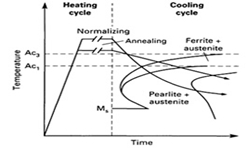

Normalizing is a heat treatment process for making material softer but does not produce the uniform material properties of annealing.A material can be normalized by heating it to a specific temperature and then letting the material cool to room temperature outside of the oven. This treatment refines the grain size and improves the uniformity of microstructure and properties of hot rolled steel.

We can supply follows heat treatment services:

Normalizing, Annealing, Quenching, Tempering, Carburizing, Nitriding, High-frequency surface hardening and other processing services.

And we can strictly enforce the national standards.

And we have follows heating equipment:

Pit furnace: Dia1300mm max, Length9500mm max.

Salt bath furnace: Length1900mm max, Width1600mm max, Height900mm max.

Trolley furnace: Legth15000mm max, Width6000mm max, Height6000mm max.

Tunnel type continuous reheating furnace:dia30mm-dia250mm

Induction quenching line: dia15mm-dia120mm

Normalizing cooling fan can be used in combination of wind capacity air-cooled systems.