154CM Blade Stainless Steel Manufacturer

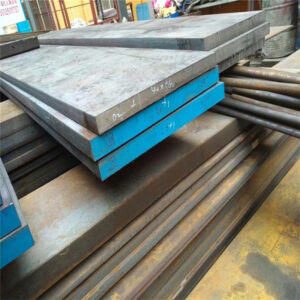

We are a prominent and large-scale professional manufacturer specializing in the production of 154CM stainless steel flat bars, steel plates, and sheets. We welcome your inquiries with competitive pricing, unwavering product quality, and abundant supply capacity. Feel free to reach out to us for any of your steel needs; we guarantee both cost-effectiveness and consistent product excellence. Your satisfaction is our priority, and we are ready to meet your demands with a substantial inventory and reliable product quality. Contact us today for a quote and experience our commitment to delivering top-notch steel products.

154CM Supplying

Shape: Flat, Sheet, Round

Heat-treatment: Annealed, Hardened

Surface: Black, Bright

Please send your inquiry to info@fushunspecialsteel.com

What is 154CM?

154CM is a type of stainless steel developed and manufactured in the United States by Crucible Materials Corporation. 154CM is a modification of martensitic stainless steel type 440C to which molybdenum has been added.

154CM Chemical Component

| Carbon | Chromium | Manganese | Molybdenum | Silicon | Iron |

| 1.05% | 14.00% | 0.50% | 4.00% | 0.30% | 80.15% |

Property of 154CM

| Hardness range | 60 to 61HRC |

| Classification | Hard steel |

| Preheating temperature | 14000F (7600C) |

| Austenitizing time | 30 to 60 minutes |

| Austenitizing temperature | 1900-2000°F (1037-1093°C) |

| Quenching method | Oil or positive pressure (4 bars minimum) |

| Quenching temperature | Below 1250F (500C) |

| Optional treatment | Salt bath treatment (to about 1000°F (540°C)) to achieve highest toughness level |

Uses of 154CM

Sometimes referred to as the crucible stainless steel, 154CM is one of the newer stainless steels on the market. There are a few manufacturers as we mentioned earlier, and depending on a few different factors, it may be considered better than (or at least as good as) 440C stainless steel. A popular use for 154CM is in survival knives that are often exposed to harsh elements like salt water for extended periods.

It’s also a very common steel used for cutlery, ball bearings, valve ports and metallic bushings. Many well-known survival and EDC knife makers use the steel liberally. Companies like Boker, Protech, Benchmade and Gerber are among a long list of bladesmiths that love the steel.