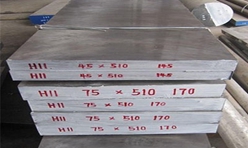

1.2343 H11 Hot Work Steels

1 1.2343 Introduction:

1.2343 Chromium hot work tool steels are designated as group H steels according to the AISI classification system. This series of steels start from H1 to H19. The most commonly used chromium hot work steels are H11, H12, and H13, which can be air hardened in 150 mm thick sections. The steels are subjected to minimal distortion during hardening due to their balanced alloy content. The tools produced from chromium hot work steels can be cooled using water without damage as these steels have low carbon and alloy contents.

This article will give an overview of H11 chromium hot work steels, which have low carbon content and good toughness. These hot work steels can be deep hardened by heat treatment and air-quenching.

We can provide more services:

1、Hardening and tempering

2、Vacuum heat treatment

3、Polished bright surface

4、Milling bright surface

5、CNC machine

6、Deep drilling

7、Cut into small pieces

8、Make it closer to the mold

Welcome to inquiry price from drawing

Cutting:

Precision cutting to standard dimensions

Custom cutting according to client specifications

Surface Grinding/Polishing:

Thickness tolerance: -0 to +0.1mm

Flatness: 0.01/100mm

Surface roughness: Ra ≤1.6 or Rz ≤6.3

2 1.2343 Applications:

1.2343 H11 Hot Work Steels is often used for highly stressed structural parts such as aircraft landing gear. It resists softening at temperatures up to 1000 F while retaining good ductility and toughness even at strength levels on the order of 275 ksi.

3 Quality Standard:

ASTM A681 Standard Specification for Tool Steel

4 All Grades Comparison:

| ASTM | AFNOR | DIN | UNI | JIS | B.S. |

|---|---|---|---|---|---|

| H11 | Z 38 CDV 5 | 1.2343 | T20811 | SKD6 | BH 11 |

5 1.2343 Chemical Composition(%):

| C | Si | Mn | P | S | Cr | V | Mo |

|---|---|---|---|---|---|---|---|

| 0.33-0.43 | 0.80-1.25 | 0.20-0.60 | 0.030 max | 0.030 max | 4.75-5.50 | 0.30-0.60 | 1.10-1.60 |

6 HEAT TREATMENT:

FORGING: H11 hot work steels are forged at 1121°C (2050°F). For this type of steels, forging below 899°C (1650°F) is not preferable.

ANNEALING: H11 hot work steels are annealed at 871°C (1600°F) and slowly cooled at 4°C (40°F) in the furnace.

HARDENING: Preheat to 1500 F and then heat to 1850 F and hold for 15 to 40 minutes. Air cool (air quench).

TEMPERING: Tempering is carried out on H11 tool steels at temperature ranging from 538 to 649°C (1000 to 1200°F) to obtain Rockwell C hardness of 54 to 38. Double tempering can also be performed in these steels every one hour at the preferred tempering temperature.

7 Mechanical Properties:

| Properties | Metric | Imperial |

|---|---|---|

| Hardness, Rockwell C (air cooled from 982°C, 45 mins) | 52.5 | 52.5 |

| Hardness, Rockwell C (air cooled from 1010°C, 45 mins) | 56 | 56 |

| Hardness, Rockwell C (air cooled from 1038°C, 45 mins) | 57 | 57 |

| Modulus of elasticity | 207 GPa | 30000 ksi |

| Modulus of elasticity (@538°C/1000°F) | 159 GPa | 23000 ksi |

| Modulus of elasticity (@204°C/400°F) | 190 GPa | 27500 ksi |

| Charpy impact (V-notch; air cooled from 1010°C;535°C temper temperature) | 13.6 J | 10.0 ft-lb |

| Charpy impact (V-notch; air cooled from 1010°C;650°C temper temperature) | 27.1 J | 20.0 ft-lb |

| Charpy impact (V-notch; air cooled from 1010°C;370°C temper temperature) | 33.9 J | 25.0 ft-lb |

| Machinability (1% carbon steel) | 75.0 – 80.0% | 75.0 – 80.0% |

| Poisson’s ratio | 0.27-0.30 | 0.27-0.30 |

8 Mill′s test certificate:

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.